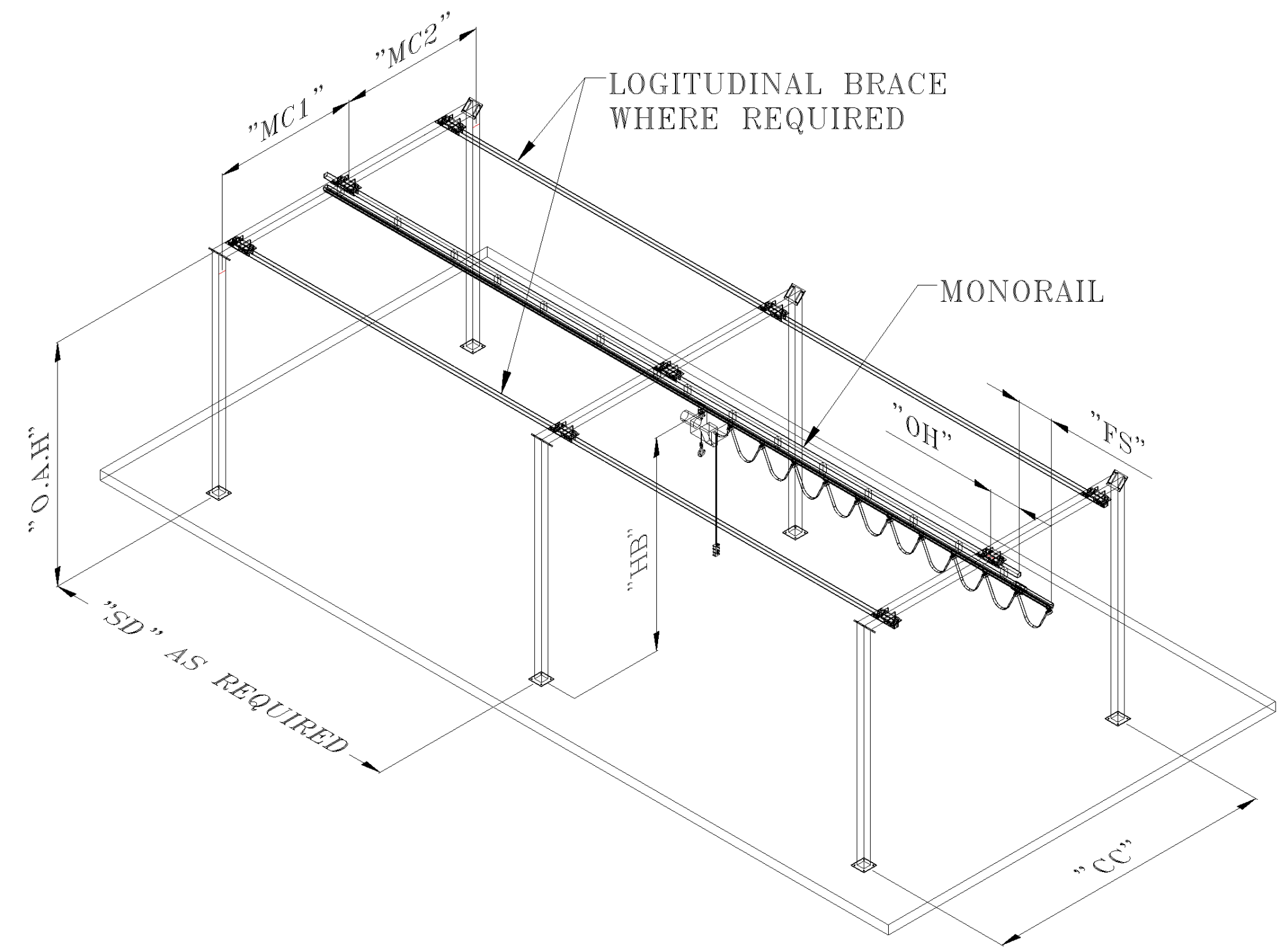

Ceiling Mounted & Free Standing Monorail Systems

Since 1946, CraneVeyor has been manufacturing traditional “I” beam monorails. In 1998 we developed the TranStation Enclosed Track work area systems. TranStations are economical and efficient systems for manually moving loads up to 4000#. Approximately 1 pound of force is required to move 100 pounds so that pushing with only 10# of force can move a 1000# load. TranStation Ceiling Mounted monorails provide ease of operation, ruggedness and value.

TRANSTATION: Ceiling Mounted & Free Standing Monorail Systems

Ceiling mounted cranes are pre-engineered systems, simple to layout and easy to install. The standard hangers are clamp type with hanger rods, but there are a variety of hanger methods available to fit your requirements. Free Standing TranStation monorails are independent of overhead support structure.

CAPACITY

250 to 4000 Lbs

HEIGHT

Up to 18′-0″

LENGTH

Up to 123′-0″

Ceiling Mounted Monorail Systems

A Ceiling Mounted TranStation is the cost effective and efficient solution when a qualified engineer determines that the overhead structure will adequately support the monorail loads, and the structure is properly positioned so that the monorail serves your handling area. All supports are overhead so that there are no floor support columns required.

The standard ceiling suspension system uses adjustable hanger brackets that attach to level steel beams with flange width to 8” and thickness to 7/16″. Threaded hanger rods (to 72″ long) are provided to level the monorail, and sway bracing is used to stabilize the system. This standard system is shown in the technical and dimension pages. Many optional suspension methods are available for a TranStation Ceiling Mounted monorail. If the standard system is not appropriate or cost effective for your structure we can provide one of our pre-engineered options or design the best system for your requirement. An optional suspension system is usually less expensive than redesigning your structure. Your ceiling support structure information should be provided with your inquiry for an optional hanger system.

1. Standard Hanger System

2. Hangers from Wood Beams

3. Direct Bolt Mount to Beam Bracket

4. Direct Bolt Mount to Concrete Wall

A few of the hanger systems available are shown below:

Ceiling Mounted Monorail Systems FEATURES INCLUDES:

TranStation Work Area Monorail Systems

TranStation enclosed track monorail systems offer efficient, pre-engineered solutions for manually handling loads up to 4,000 lbs, whether a structural ceiling is available or not. Both Free Standing and Ceiling Mounted systems are engineered for durability, modularity, and ease of installation, and are available in a wide range of configurations.

Free Standing TranStation Systems

Ideal when the overhead structure is unavailable or inadequate to support monorail loads. These systems include structural steel columns and frames to create a self-supporting solution.

Support Distance (SD): 20′-0, 25′-0, or 30′-0 maximum hanger centers with trussed track.

Modular Bay Spacing: Divided equally unless otherwise specified.

Meets Seismic Zone 4 requirements.

Free Standing System Components:

Hoist Trolley

Monorail

Splice Assemblies

Stiffeners (as required for longitudinal stability)

Festoon Trolleys

4-Conductor #14 Flat Cable or 1/2″ Air Hose

Festoon Clamps and Stack-up Sections

End Stops

Part Number Breakdown Provided

Ceiling Mounted TranStation Systems

A cost-effective and space-saving option when the overhead structure can safely carry the monorail loads. This setup eliminates the need for floor columns, making it ideal for maximizing work area clearance.

Support Distance (SD): 20′, 25′, or 30′ maximum with trussed track.

Runway Span: 6′ (plain track) or up to 30′ (trussed track)

Bridge Span/Length: Up to 32′ bridge span and 34′ bridge length

Hundreds of pre-engineered models available from 250 lbs to 4,000 lbs capacity.

Ceiling Mounted System Components:

Enclosed Track Bridge with end trucks, stops, and trolley for hook-on hoists/devices

Enclosed track runways with upper hanger assemblies, splice assemblies, and mounting hardware

Festooned electrical systems with trolleys, flat cable or air hose, clamps, and stack-up sections

Layout drawings, installation manuals, and engineering instructions included

TranStation Ceiling Mounted systems include:

Enclosed Track Bridge, with end trucks, stops and trolley for a hook-on hoist/device.

Enclosed track runways, complete with beam type upper hanger assemblies, splice assemblies and mounting hardware.

Festooned electrical system for bridge and runway, complete with trolleys, 4-conductor #14 flat cable, clamps and stack-up system.

A layout drawing, assembly instructions, and manuals are provided with each system.

Plain Track Configuration to 6' Runway Support Centers