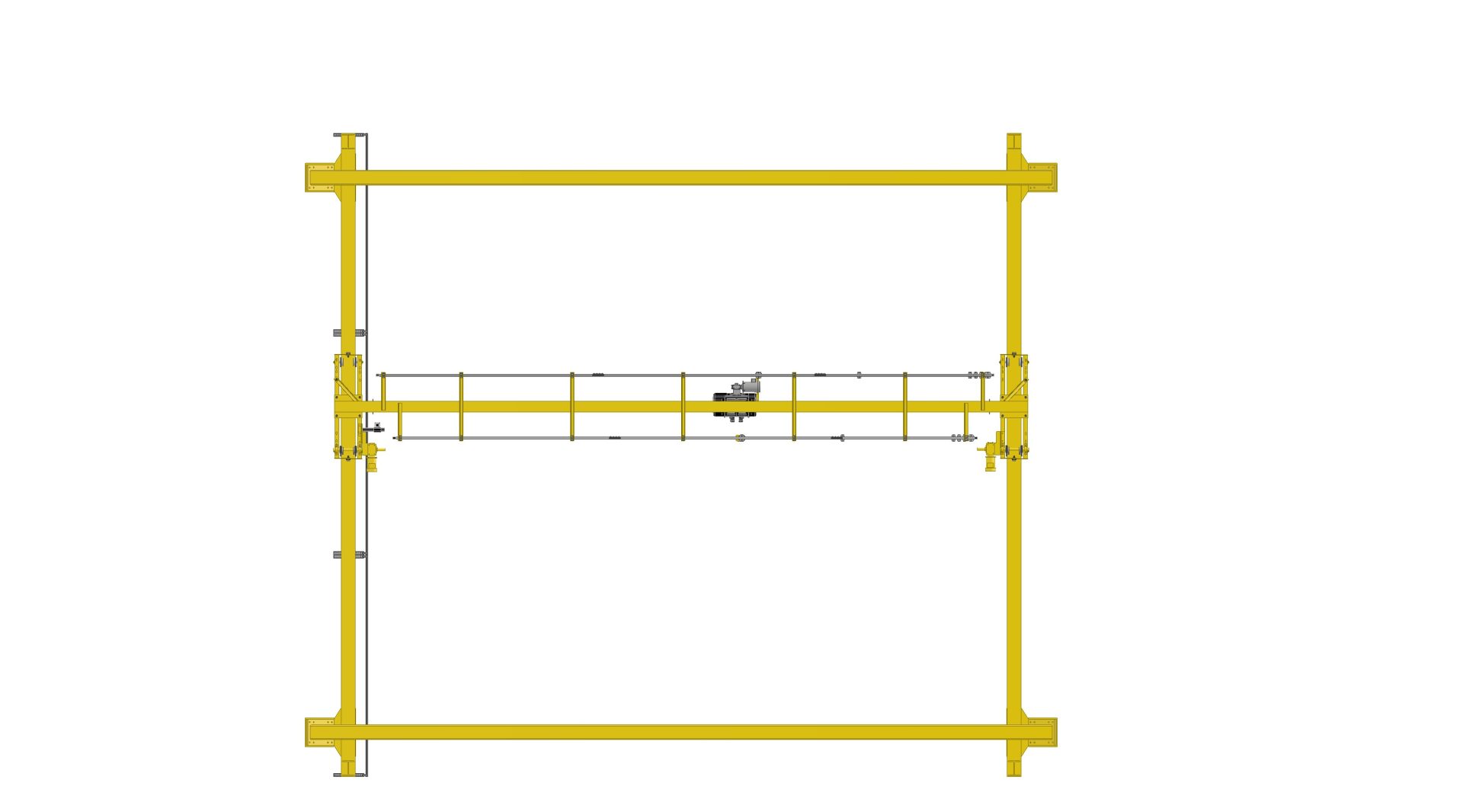

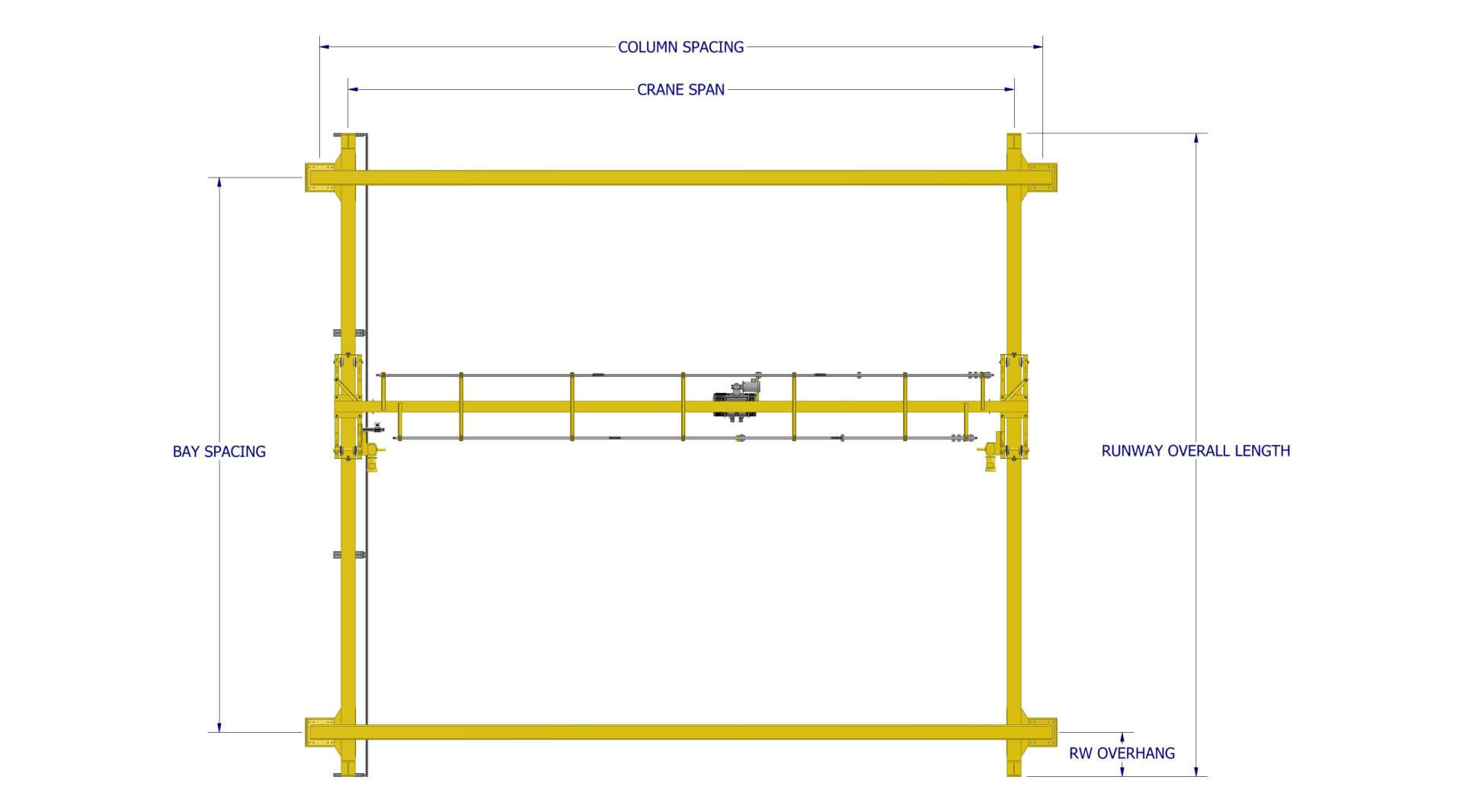

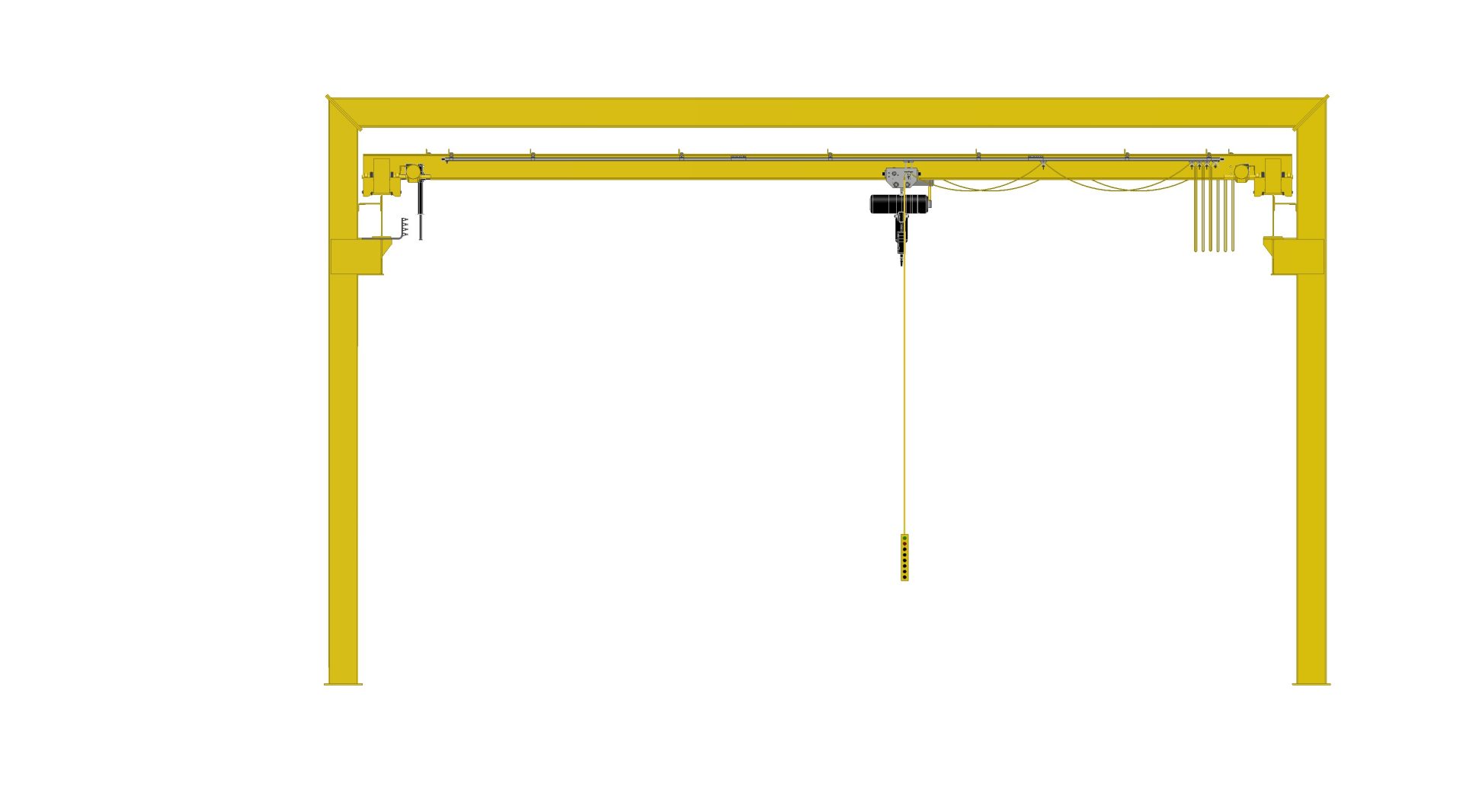

The Free Standing Overhead Crane from CraneVeyor is a space-saving, top running system designed for efficient lifting in facilities without existing support structures. With its single girder construction, this crane delivers reliable performance for shops, warehouses, and production floors.Engineered for ease of installation and long-term durability, this system eliminates the need for building tie-ins. It’s the ideal solution for open bays, retrofits, and facilities with floor-level clearance challenges. With high-capacity load handling and a modular design, it adapts to various ceiling heights, bay sizes, and operational layouts.

This crane system is built to CMAA Class C or D standards, offering smooth, low-maintenance operation with the strength and precision needed for industrial workloads.

Key Applications:

- Manufacturing

- Warehouse material handling

- Steel shops and fabrication centers

- Retrofit crane solutions

Ready to improve productivity with a free-standing overhead bridge crane? Contact CraneVeyor today for a quote and expert guidance.

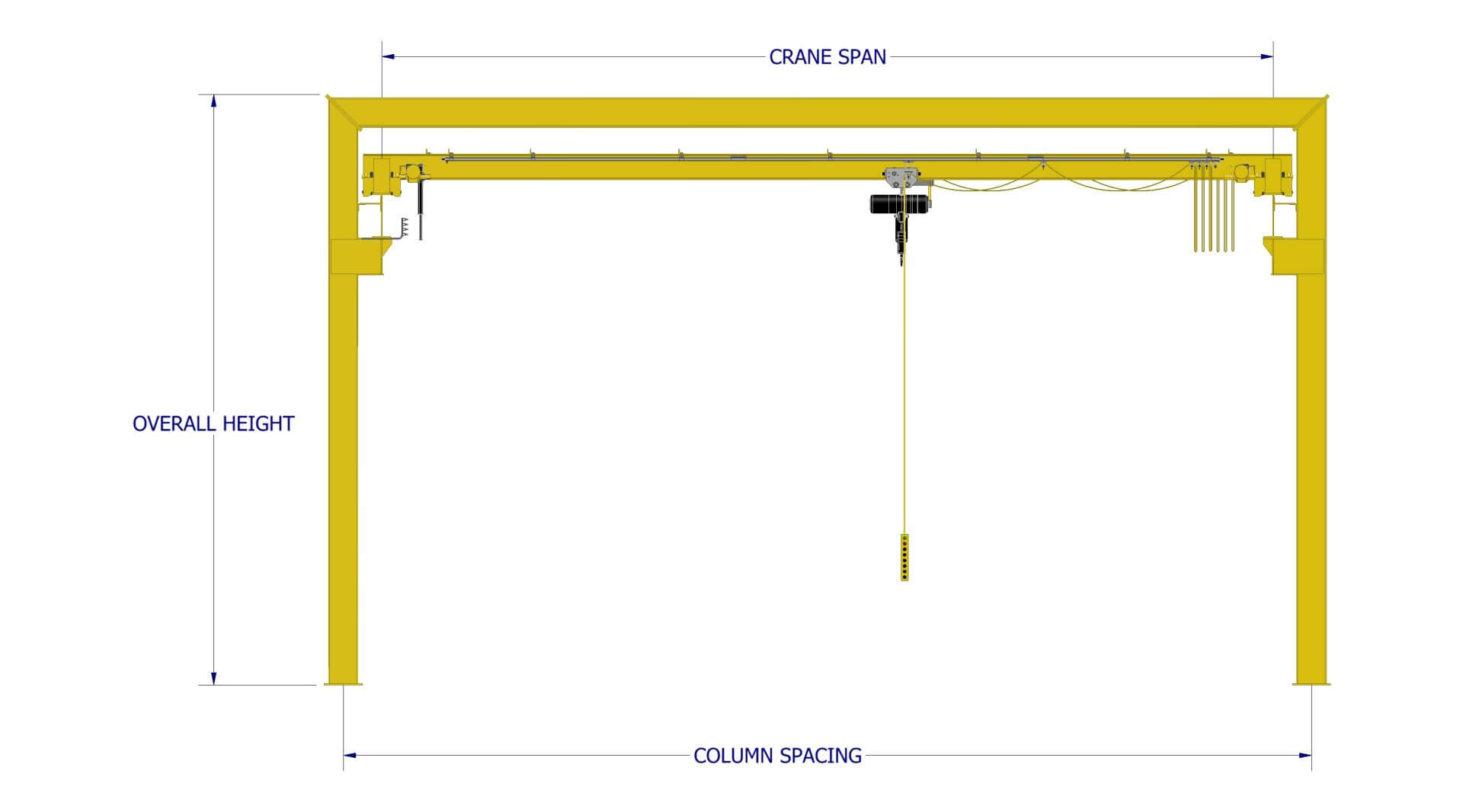

| Model Number | Crane Type | Capacity | Column Centers | Runway Length | Number Of Bays | Max Bay Spacing | Overall Height | Weight | Price |

|---|---|---|---|---|---|---|---|---|---|

| TT-2-18-20-20-20 | TT | 2 | 18 | 20 | 1 | 20 | 20 | 8484 | 0 |

| TT-2-18-40-20-20 | TT | 2 | 18 | 40 | 2 | 20 | 20 | 12007 | 0 |

| TT-2-18-60-20-20 | TT | 2 | 18 | 60 | 3 | 20 | 20 | 15530 | 0 |

| TT-2-18-80-20-20 | TT | 2 | 18 | 80 | 4 | 20 | 20 | 19053 | 0 |

| TT-2-18-25-25-20 | TT | 2 | 18 | 25 | 1 | 25 | 20 | 9504 | 0 |

| TT-2-18-50-25-20 | TT | 2 | 18 | 50 | 2 | 25 | 20 | 14047 | 0 |

| TT-2-18-75-25-20 | TT | 2 | 18 | 75 | 3 | 25 | 20 | 18590 | 0 |

| TT-2-18-100-25-20 | TT | 2 | 18 | 100 | 4 | 25 | 20 | 23133 | 0 |

| TT-2-18-30-30-20 | TT | 2 | 18 | 30 | 1 | 30 | 20 | 10304 | 0 |

| TT-2-18-60-30-20 | TT | 2 | 18 | 60 | 2 | 30 | 20 | 15647 | 0 |

| TT-2-18-90-30-20 | TT | 2 | 18 | 90 | 3 | 30 | 20 | 20990 | 0 |

| TT-2-18-120-30-20 | TT | 2 | 18 | 120 | 4 | 30 | 20 | 26333 | 0 |

| TT-2-18-20-20-24 | TT | 2 | 18 | 20 | 1 | 20 | 24 | 8863 | 0 |

| TT-2-18-40-20-24 | TT | 2 | 18 | 40 | 2 | 20 | 24 | 12575 | 0 |

| TT-2-18-60-20-24 | TT | 2 | 18 | 60 | 3 | 20 | 24 | 16288 | 0 |

| TT-2-18-80-20-24 | TT | 2 | 18 | 80 | 4 | 20 | 24 | 20000 | 0 |

| TT-2-18-25-25-24 | TT | 2 | 18 | 25 | 1 | 25 | 24 | 9883 | 0 |

| TT-2-18-50-25-24 | TT | 2 | 18 | 50 | 2 | 25 | 24 | 14615 | 0 |

| TT-2-18-75-25-24 | TT | 2 | 18 | 75 | 3 | 25 | 24 | 19348 | 0 |

| TT-2-18-100-25-24 | TT | 2 | 18 | 100 | 4 | 25 | 24 | 24080 | 0 |

| TT-2-18-30-30-24 | TT | 2 | 18 | 30 | 1 | 30 | 24 | 10683 | 0 |

| TT-2-18-60-30-24 | TT | 2 | 18 | 60 | 2 | 30 | 24 | 16215 | 0 |

| TT-2-18-90-30-24 | TT | 2 | 18 | 90 | 3 | 30 | 24 | 21748 | 0 |

| TT-2-18-120-30-24 | TT | 2 | 18 | 120 | 4 | 30 | 24 | 27280 | 0 |

| TT-2-28-20-20-20 | TT | 2 | 28 | 20 | 1 | 20 | 20 | 9848 | 0 |

| TT-2-28-40-20-20 | TT | 2 | 28 | 40 | 2 | 20 | 20 | 13738 | 0 |

| TT-2-28-60-20-20 | TT | 2 | 28 | 60 | 3 | 20 | 20 | 17627 | 0 |

| TT-2-28-80-20-20 | TT | 2 | 28 | 80 | 4 | 20 | 20 | 21517 | 0 |

| TT-2-28-25-25-20 | TT | 2 | 28 | 25 | 1 | 25 | 20 | 10868 | 0 |

| TT-2-28-50-25-20 | TT | 2 | 28 | 50 | 2 | 25 | 20 | 15778 | 0 |

| TT-2-28-75-25-20 | TT | 2 | 28 | 75 | 3 | 25 | 20 | 20687 | 0 |

| TT-2-28-100-25-20 | TT | 2 | 28 | 100 | 4 | 25 | 20 | 25597 | 0 |

| TT-2-28-30-30-20 | TT | 2 | 28 | 30 | 1 | 30 | 20 | 11668 | 0 |

| TT-2-28-60-30-20 | TT | 2 | 28 | 60 | 2 | 30 | 20 | 17378 | 0 |

| TT-2-28-90-30-20 | TT | 2 | 28 | 90 | 3 | 30 | 20 | 23087 | 0 |

| TT-2-28-120-30-20 | TT | 2 | 28 | 120 | 4 | 30 | 20 | 28797 | 0 |

| TT-2-28-20-20-24 | TT | 2 | 28 | 20 | 1 | 20 | 24 | 10203 | 0 |

| TT-2-28-40-20-24 | TT | 2 | 28 | 40 | 2 | 20 | 24 | 14270 | 0 |

| TT-2-28-60-20-24 | TT | 2 | 28 | 60 | 3 | 20 | 24 | 18337 | 0 |

| TT-2-28-80-20-24 | TT | 2 | 28 | 80 | 4 | 20 | 24 | 22404 | 0 |

| TT-2-28-25-25-24 | TT | 2 | 28 | 25 | 1 | 25 | 24 | 11223 | 0 |

| TT-2-28-50-25-24 | TT | 2 | 28 | 50 | 2 | 25 | 24 | 16310 | 0 |

| TT-2-28-75-25-24 | TT | 2 | 28 | 75 | 3 | 25 | 24 | 21397 | 0 |

| TT-2-28-100-25-24 | TT | 2 | 28 | 100 | 4 | 25 | 24 | 26484 | 0 |

| TT-2-28-30-30-24 | TT | 2 | 28 | 30 | 1 | 30 | 24 | 12023 | 0 |

| TT-2-28-60-30-24 | TT | 2 | 28 | 60 | 2 | 30 | 24 | 17910 | 0 |

| TT-2-28-90-30-24 | TT | 2 | 28 | 90 | 3 | 30 | 24 | 23797 | 0 |

| TT-2-28-120-30-24 | TT | 2 | 28 | 120 | 4 | 30 | 24 | 29684 | 0 |

| TT-2-38-20-20-20 | TT | 2 | 38 | 20 | 1 | 20 | 20 | 12964 | 0 |

| TT-2-38-40-20-20 | TT | 2 | 38 | 40 | 2 | 20 | 20 | 17881 | 0 |

| TT-2-38-60-20-20 | TT | 2 | 38 | 60 | 3 | 20 | 20 | 22799 | 0 |

| TT-2-38-80-20-20 | TT | 2 | 38 | 80 | 4 | 20 | 20 | 27716 | 0 |

| TT-2-38-25-25-20 | TT | 2 | 38 | 25 | 1 | 25 | 20 | 13984 | 0 |

| TT-2-38-50-25-20 | TT | 2 | 38 | 50 | 2 | 25 | 20 | 19921 | 0 |

| TT-2-38-75-25-20 | TT | 2 | 38 | 75 | 3 | 25 | 20 | 25859 | 0 |

| TT-2-38-100-25-20 | TT | 2 | 38 | 100 | 4 | 25 | 20 | 31796 | 0 |

| TT-2-38-30-30-20 | TT | 2 | 38 | 30 | 1 | 30 | 20 | 14784 | 0 |

| TT-2-38-60-30-20 | TT | 2 | 38 | 60 | 2 | 30 | 20 | 21521 | 0 |

| TT-2-38-90-30-20 | TT | 2 | 38 | 90 | 3 | 30 | 20 | 28259 | 0 |

| TT-2-38-120-30-20 | TT | 2 | 38 | 120 | 4 | 30 | 20 | 34996 | 0 |

| TT-2-38-20-20-24 | TT | 2 | 38 | 20 | 1 | 20 | 24 | 13486 | 0 |

| TT-2-38-40-20-24 | TT | 2 | 38 | 40 | 2 | 20 | 24 | 18664 | 0 |

| TT-2-38-60-20-24 | TT | 2 | 38 | 60 | 3 | 20 | 24 | 23843 | 0 |

| TT-2-38-80-20-24 | TT | 2 | 38 | 80 | 4 | 20 | 24 | 29022 | 0 |

| TT-2-38-25-25-24 | TT | 2 | 38 | 25 | 1 | 25 | 24 | 14506 | 0 |

| TT-2-38-50-25-24 | TT | 2 | 38 | 50 | 2 | 25 | 24 | 20704 | 0 |

| TT-2-38-75-25-24 | TT | 2 | 38 | 75 | 3 | 25 | 24 | 26903 | 0 |

| TT-2-38-100-25-24 | TT | 2 | 38 | 100 | 4 | 25 | 24 | 33102 | 0 |

| TT-2-38-30-30-24 | TT | 2 | 38 | 30 | 1 | 30 | 24 | 15306 | 0 |

| TT-2-38-60-30-24 | TT | 2 | 38 | 60 | 2 | 30 | 24 | 22304 | 0 |

| TT-2-38-90-30-24 | TT | 2 | 38 | 90 | 3 | 30 | 24 | 29303 | 0 |

| TT-2-38-120-30-24 | TT | 2 | 38 | 120 | 4 | 30 | 24 | 36302 | 0 |

| TT-2-46-20-20-20 | TT | 2 | 46 | 20 | 1 | 20 | 20 | 15837 | 0 |

| TT-2-46-40-20-20 | TT | 2 | 46 | 40 | 2 | 20 | 20 | 21308 | 0 |

| TT-2-46-60-20-20 | TT | 2 | 46 | 60 | 3 | 20 | 20 | 26779 | 0 |

| TT-2-46-80-20-20 | TT | 2 | 46 | 80 | 4 | 20 | 20 | 32250 | 0 |

| TT-2-46-25-25-20 | TT | 2 | 46 | 25 | 1 | 25 | 20 | 16857 | 0 |

| TT-2-46-50-25-20 | TT | 2 | 46 | 50 | 2 | 25 | 20 | 23348 | 0 |

| TT-2-46-75-25-20 | TT | 2 | 46 | 75 | 3 | 25 | 20 | 29839 | 0 |

| TT-2-46-100-25-20 | TT | 2 | 46 | 100 | 4 | 25 | 20 | 36330 | 0 |

| TT-2-46-30-30-20 | TT | 2 | 46 | 30 | 1 | 30 | 20 | 17657 | 0 |

| TT-2-46-60-30-20 | TT | 2 | 46 | 60 | 2 | 30 | 20 | 24948 | 0 |

| TT-2-46-90-30-20 | TT | 2 | 46 | 90 | 3 | 30 | 20 | 32239 | 0 |

| TT-2-46-120-30-20 | TT | 2 | 46 | 120 | 4 | 30 | 20 | 39530 | 0 |

| TT-2-46-20-20-24 | TT | 2 | 46 | 20 | 1 | 20 | 24 | 16382 | 0 |

| TT-2-46-40-20-24 | TT | 2 | 46 | 40 | 2 | 20 | 24 | 22126 | 0 |

| TT-2-46-60-20-24 | TT | 2 | 46 | 60 | 3 | 20 | 24 | 27870 | 0 |

| TT-2-46-80-20-24 | TT | 2 | 46 | 80 | 4 | 20 | 24 | 33614 | 0 |

| TT-2-46-25-25-24 | TT | 2 | 46 | 25 | 1 | 25 | 24 | 17402 | 0 |

| TT-2-46-50-25-24 | TT | 2 | 46 | 50 | 2 | 25 | 24 | 24166 | 0 |

| TT-2-46-75-25-24 | TT | 2 | 46 | 75 | 3 | 25 | 24 | 30930 | 0 |

| TT-2-46-100-25-24 | TT | 2 | 46 | 100 | 4 | 25 | 24 | 37694 | 0 |

| TT-2-46-30-30-24 | TT | 2 | 46 | 30 | 1 | 30 | 24 | 18202 | 0 |

| TT-2-46-60-30-24 | TT | 2 | 46 | 60 | 2 | 30 | 24 | 25766 | 0 |

| TT-2-46-90-30-24 | TT | 2 | 46 | 90 | 3 | 30 | 24 | 33330 | 0 |

| TT-2-46-120-30-24 | TT | 2 | 46 | 120 | 4 | 30 | 24 | 40894 | 0 |

| TT-2-58-20-20-20 | TT | 2 | 58 | 20 | 1 | 20 | 20 | 26540 | 0 |

| TT-2-58-40-20-20 | TT | 2 | 58 | 40 | 2 | 20 | 20 | 36571 | 0 |

| TT-2-58-60-20-20 | TT | 2 | 58 | 60 | 3 | 20 | 20 | 46602 | 0 |

| TT-2-58-80-20-20 | TT | 2 | 58 | 80 | 4 | 20 | 20 | 56634 | 0 |

| TT-2-58-25-25-20 | TT | 2 | 58 | 25 | 1 | 25 | 20 | 27560 | 0 |

| TT-2-58-50-25-20 | TT | 2 | 58 | 50 | 2 | 25 | 20 | 38611 | 0 |

| TT-2-58-75-25-20 | TT | 2 | 58 | 75 | 3 | 25 | 20 | 49662 | 0 |

| TT-2-58-100-25-20 | TT | 2 | 58 | 100 | 4 | 25 | 20 | 60714 | 0 |

| TT-2-58-30-30-20 | TT | 2 | 58 | 30 | 1 | 30 | 20 | 28360 | 0 |

| TT-2-58-60-30-20 | TT | 2 | 58 | 60 | 2 | 30 | 20 | 40211 | 0 |

| TT-2-58-90-30-20 | TT | 2 | 58 | 90 | 3 | 30 | 20 | 52062 | 0 |

| TT-2-58-120-30-20 | TT | 2 | 58 | 120 | 4 | 30 | 20 | 63914 | 0 |

| TT-2-58-20-20-24 | TT | 2 | 58 | 20 | 1 | 20 | 24 | 27632 | 0 |

| TT-2-58-40-20-24 | TT | 2 | 58 | 40 | 2 | 20 | 24 | 38210 | 0 |

| TT-2-58-60-20-24 | TT | 2 | 58 | 60 | 3 | 20 | 24 | 48788 | 0 |

| TT-2-58-80-20-24 | TT | 2 | 58 | 80 | 4 | 20 | 24 | 59365 | 0 |

| TT-2-58-25-25-24 | TT | 2 | 58 | 25 | 1 | 25 | 24 | 28652 | 0 |

| TT-2-58-50-25-24 | TT | 2 | 58 | 50 | 2 | 25 | 24 | 40250 | 0 |

| TT-2-58-75-25-24 | TT | 2 | 58 | 75 | 3 | 25 | 24 | 51848 | 0 |

| TT-2-58-100-25-24 | TT | 2 | 58 | 100 | 4 | 25 | 24 | 63445 | 0 |

| TT-2-58-30-30-24 | TT | 2 | 58 | 30 | 1 | 30 | 24 | 29452 | 0 |

| TT-2-58-60-30-24 | TT | 2 | 58 | 60 | 2 | 30 | 24 | 41850 | 0 |

| TT-2-58-90-30-24 | TT | 2 | 58 | 90 | 3 | 30 | 24 | 54248 | 0 |

| TT-2-58-120-30-24 | TT | 2 | 58 | 120 | 4 | 30 | 24 | 66645 | 0 |

| TT-3-18-20-20-20 | TT | 3 | 18 | 20 | 1 | 20 | 20 | 8789 | 0 |

| TT-3-18-40-20-20 | TT | 3 | 18 | 40 | 2 | 20 | 20 | 12512 | 0 |

| TT-3-18-60-20-20 | TT | 3 | 18 | 60 | 3 | 20 | 20 | 16235 | 0 |

| TT-3-18-80-20-20 | TT | 3 | 18 | 80 | 4 | 20 | 20 | 19958 | 0 |

| TT-3-18-25-25-20 | TT | 3 | 18 | 25 | 1 | 25 | 20 | 9609 | 0 |

| TT-3-18-50-25-20 | TT | 3 | 18 | 50 | 2 | 25 | 20 | 14152 | 0 |

| TT-3-18-75-25-20 | TT | 3 | 18 | 75 | 3 | 25 | 20 | 18695 | 0 |

| TT-3-18-100-25-20 | TT | 3 | 18 | 100 | 4 | 25 | 20 | 23238 | 0 |

| TT-3-18-30-30-20 | TT | 3 | 18 | 30 | 1 | 30 | 20 | 10307 | 0 |

| TT-3-18-60-30-20 | TT | 3 | 18 | 60 | 2 | 30 | 20 | 15548 | 0 |

| TT-3-18-90-30-20 | TT | 3 | 18 | 90 | 3 | 30 | 20 | 20789 | 0 |

| TT-3-18-120-30-20 | TT | 3 | 18 | 120 | 4 | 30 | 20 | 26030 | 0 |

| TT-3-18-20-20-24 | TT | 3 | 18 | 20 | 1 | 20 | 24 | 9168 | 0 |

| TT-3-18-40-20-24 | TT | 3 | 18 | 40 | 2 | 20 | 24 | 13080 | 0 |

| TT-3-18-60-20-24 | TT | 3 | 18 | 60 | 3 | 20 | 24 | 16993 | 0 |

| TT-3-18-80-20-24 | TT | 3 | 18 | 80 | 4 | 20 | 24 | 20905 | 0 |

| TT-3-18-25-25-24 | TT | 3 | 18 | 25 | 1 | 25 | 24 | 9988 | 0 |

| TT-3-18-50-25-24 | TT | 3 | 18 | 50 | 2 | 25 | 24 | 14720 | 0 |

| TT-3-18-75-25-24 | TT | 3 | 18 | 75 | 3 | 25 | 24 | 19453 | 0 |

| TT-3-18-100-25-24 | TT | 3 | 18 | 100 | 4 | 25 | 24 | 24185 | 0 |

| TT-3-18-30-30-24 | TT | 3 | 18 | 30 | 1 | 30 | 24 | 10686 | 0 |

| TT-3-18-60-30-24 | TT | 3 | 18 | 60 | 2 | 30 | 24 | 16116 | 0 |

| TT-3-18-90-30-24 | TT | 3 | 18 | 90 | 3 | 30 | 24 | 21547 | 0 |

| TT-3-18-120-30-24 | TT | 3 | 18 | 120 | 4 | 30 | 24 | 26977 | 0 |

| TT-3-28-20-20-20 | TT | 3 | 28 | 20 | 1 | 20 | 20 | 10309 | 0 |

| TT-3-28-40-20-20 | TT | 3 | 28 | 40 | 2 | 20 | 20 | 14399 | 0 |

| TT-3-28-60-20-20 | TT | 3 | 28 | 60 | 3 | 20 | 20 | 18489 | 0 |

| TT-3-28-80-20-20 | TT | 3 | 28 | 80 | 4 | 20 | 20 | 22579 | 0 |

| TT-3-28-25-25-20 | TT | 3 | 28 | 25 | 1 | 25 | 20 | 11129 | 0 |

| TT-3-28-50-25-20 | TT | 3 | 28 | 50 | 2 | 25 | 20 | 16039 | 0 |

| TT-3-28-75-25-20 | TT | 3 | 28 | 75 | 3 | 25 | 20 | 20949 | 0 |

| TT-3-28-100-25-20 | TT | 3 | 28 | 100 | 4 | 25 | 20 | 25859 | 0 |

| TT-3-28-30-30-20 | TT | 3 | 28 | 30 | 1 | 30 | 20 | 11827 | 0 |

| TT-3-28-60-30-20 | TT | 3 | 28 | 60 | 2 | 30 | 20 | 17435 | 0 |

| TT-3-28-90-30-20 | TT | 3 | 28 | 90 | 3 | 30 | 20 | 23043 | 0 |

| TT-3-28-120-30-20 | TT | 3 | 28 | 120 | 4 | 30 | 20 | 28651 | 0 |

| TT-3-28-20-20-24 | TT | 3 | 28 | 20 | 1 | 20 | 24 | 10664 | 0 |

| TT-3-28-40-20-24 | TT | 3 | 28 | 40 | 2 | 20 | 24 | 14931 | 0 |

| TT-3-28-60-20-24 | TT | 3 | 28 | 60 | 3 | 20 | 24 | 19199 | 0 |

| TT-3-28-80-20-24 | TT | 3 | 28 | 80 | 4 | 20 | 24 | 23466 | 0 |

| TT-3-28-25-25-24 | TT | 3 | 28 | 25 | 1 | 25 | 24 | 11484 | 0 |

| TT-3-28-50-25-24 | TT | 3 | 28 | 50 | 2 | 25 | 24 | 16571 | 0 |

| TT-3-28-75-25-24 | TT | 3 | 28 | 75 | 3 | 25 | 24 | 21659 | 0 |

| TT-3-28-100-25-24 | TT | 3 | 28 | 100 | 4 | 25 | 24 | 26746 | 0 |

| TT-3-28-30-30-24 | TT | 3 | 28 | 30 | 1 | 30 | 24 | 12182 | 0 |

| TT-3-28-60-30-24 | TT | 3 | 28 | 60 | 2 | 30 | 24 | 17967 | 0 |

| TT-3-28-90-30-24 | TT | 3 | 28 | 90 | 3 | 30 | 24 | 23753 | 0 |

| TT-3-28-120-30-24 | TT | 3 | 28 | 120 | 4 | 30 | 24 | 29538 | 0 |

| TT-3-38-20-20-20 | TT | 3 | 38 | 20 | 1 | 20 | 20 | 13574 | 0 |

| TT-3-38-40-20-20 | TT | 3 | 38 | 40 | 2 | 20 | 20 | 18691 | 0 |

| TT-3-38-60-20-20 | TT | 3 | 38 | 60 | 3 | 20 | 20 | 23809 | 0 |

| TT-3-38-80-20-20 | TT | 3 | 38 | 80 | 4 | 20 | 20 | 28926 | 0 |

| TT-3-38-25-25-20 | TT | 3 | 38 | 25 | 1 | 25 | 20 | 14394 | 0 |

| TT-3-38-50-25-20 | TT | 3 | 38 | 50 | 2 | 25 | 20 | 20331 | 0 |

| TT-3-38-75-25-20 | TT | 3 | 38 | 75 | 3 | 25 | 20 | 26269 | 0 |

| TT-3-38-100-25-20 | TT | 3 | 38 | 100 | 4 | 25 | 20 | 32206 | 0 |

| TT-3-38-30-30-20 | TT | 3 | 38 | 30 | 1 | 30 | 20 | 15092 | 0 |

| TT-3-38-60-30-20 | TT | 3 | 38 | 60 | 2 | 30 | 20 | 21727 | 0 |

| TT-3-38-90-30-20 | TT | 3 | 38 | 90 | 3 | 30 | 20 | 28363 | 0 |

| TT-3-38-120-30-20 | TT | 3 | 38 | 120 | 4 | 30 | 20 | 34998 | 0 |

| TT-3-38-20-20-24 | TT | 3 | 38 | 20 | 1 | 20 | 24 | 14096 | 0 |

| TT-3-38-40-20-24 | TT | 3 | 38 | 40 | 2 | 20 | 24 | 19474 | 0 |

| TT-3-38-60-20-24 | TT | 3 | 38 | 60 | 3 | 20 | 24 | 24853 | 0 |

| TT-3-38-80-20-24 | TT | 3 | 38 | 80 | 4 | 20 | 24 | 30232 | 0 |

| TT-3-38-25-25-24 | TT | 3 | 38 | 25 | 1 | 25 | 24 | 14916 | 0 |

| TT-3-38-50-25-24 | TT | 3 | 38 | 50 | 2 | 25 | 24 | 21114 | 0 |

| TT-3-38-75-25-24 | TT | 3 | 38 | 75 | 3 | 25 | 24 | 27313 | 0 |

| TT-3-38-100-25-24 | TT | 3 | 38 | 100 | 4 | 25 | 24 | 33512 | 0 |

| TT-3-38-30-30-24 | TT | 3 | 38 | 30 | 1 | 30 | 24 | 15614 | 0 |

| TT-3-38-60-30-24 | TT | 3 | 38 | 60 | 2 | 30 | 24 | 22510 | 0 |

| TT-3-38-90-30-24 | TT | 3 | 38 | 90 | 3 | 30 | 24 | 29407 | 0 |

| TT-3-38-120-30-24 | TT | 3 | 38 | 120 | 4 | 30 | 24 | 36304 | 0 |

| TT-3-46-20-20-20 | TT | 3 | 46 | 20 | 1 | 20 | 20 | 16406 | 0 |

| TT-3-46-40-20-20 | TT | 3 | 46 | 40 | 2 | 20 | 20 | 22077 | 0 |

| TT-3-46-60-20-20 | TT | 3 | 46 | 60 | 3 | 20 | 20 | 27748 | 0 |

| TT-3-46-80-20-20 | TT | 3 | 46 | 80 | 4 | 20 | 20 | 33419 | 0 |

| TT-3-46-25-25-20 | TT | 3 | 46 | 25 | 1 | 25 | 20 | 17226 | 0 |

| TT-3-46-50-25-20 | TT | 3 | 46 | 50 | 2 | 25 | 20 | 23717 | 0 |

| TT-3-46-75-25-20 | TT | 3 | 46 | 75 | 3 | 25 | 20 | 30208 | 0 |

| TT-3-46-100-25-20 | TT | 3 | 46 | 100 | 4 | 25 | 20 | 36699 | 0 |

| TT-3-46-30-30-20 | TT | 3 | 46 | 30 | 1 | 30 | 20 | 17924 | 0 |

| TT-3-46-60-30-20 | TT | 3 | 46 | 60 | 2 | 30 | 20 | 25113 | 0 |

| TT-3-46-90-30-20 | TT | 3 | 46 | 90 | 3 | 30 | 20 | 32302 | 0 |

| TT-3-46-120-30-20 | TT | 3 | 46 | 120 | 4 | 30 | 20 | 39491 | 0 |

| TT-3-46-20-20-24 | TT | 3 | 46 | 20 | 1 | 20 | 24 | 16951 | 0 |

| TT-3-46-40-20-24 | TT | 3 | 46 | 40 | 2 | 20 | 24 | 22895 | 0 |

| TT-3-46-60-20-24 | TT | 3 | 46 | 60 | 3 | 20 | 24 | 28839 | 0 |

| TT-3-46-80-20-24 | TT | 3 | 46 | 80 | 4 | 20 | 24 | 34783 | 0 |

| TT-3-46-25-25-24 | TT | 3 | 46 | 25 | 1 | 25 | 24 | 17771 | 0 |

| TT-3-46-50-25-24 | TT | 3 | 46 | 50 | 2 | 25 | 24 | 24535 | 0 |

| TT-3-46-75-25-24 | TT | 3 | 46 | 75 | 3 | 25 | 24 | 31299 | 0 |

| TT-3-46-100-25-24 | TT | 3 | 46 | 100 | 4 | 25 | 24 | 38063 | 0 |

| TT-3-46-30-30-24 | TT | 3 | 46 | 30 | 1 | 30 | 24 | 18469 | 0 |

| TT-3-46-60-30-24 | TT | 3 | 46 | 60 | 2 | 30 | 24 | 25931 | 0 |

| TT-3-46-90-30-24 | TT | 3 | 46 | 90 | 3 | 30 | 24 | 33393 | 0 |

| TT-3-46-120-30-24 | TT | 3 | 46 | 120 | 4 | 30 | 24 | 40855 | 0 |

| TT-3-58-20-20-20 | TT | 3 | 58 | 20 | 1 | 20 | 20 | 28033 | 0 |

| TT-3-58-40-20-20 | TT | 3 | 58 | 40 | 2 | 20 | 20 | 38264 | 0 |

| TT-3-58-60-20-20 | TT | 3 | 58 | 60 | 3 | 20 | 20 | 48495 | 0 |

| TT-3-58-80-20-20 | TT | 3 | 58 | 80 | 4 | 20 | 20 | 58727 | 0 |

| TT-3-58-25-25-20 | TT | 3 | 58 | 25 | 1 | 25 | 20 | 28853 | 0 |

| TT-3-58-50-25-20 | TT | 3 | 58 | 50 | 2 | 25 | 20 | 39904 | 0 |

| TT-3-58-75-25-20 | TT | 3 | 58 | 75 | 3 | 25 | 20 | 50955 | 0 |

| TT-3-58-100-25-20 | TT | 3 | 58 | 100 | 4 | 25 | 20 | 62007 | 0 |

| TT-3-58-30-30-20 | TT | 3 | 58 | 30 | 1 | 30 | 20 | 29551 | 0 |

| TT-3-58-60-30-20 | TT | 3 | 58 | 60 | 2 | 30 | 20 | 41300 | 0 |

| TT-3-58-90-30-20 | TT | 3 | 58 | 90 | 3 | 30 | 20 | 53049 | 0 |

| TT-3-58-120-30-20 | TT | 3 | 58 | 120 | 4 | 30 | 20 | 64799 | 0 |

| TT-3-58-20-20-24 | TT | 3 | 58 | 20 | 1 | 20 | 24 | 29125 | 0 |

| TT-3-58-40-20-24 | TT | 3 | 58 | 40 | 2 | 20 | 24 | 39903 | 0 |

| TT-3-58-60-20-24 | TT | 3 | 58 | 60 | 3 | 20 | 24 | 50681 | 0 |

| TT-3-58-80-20-24 | TT | 3 | 58 | 80 | 4 | 20 | 24 | 61458 | 0 |

| TT-3-58-25-25-24 | TT | 3 | 58 | 25 | 1 | 25 | 24 | 29945 | 0 |

| TT-3-58-50-25-24 | TT | 3 | 58 | 50 | 2 | 25 | 24 | 41543 | 0 |

| TT-3-58-75-25-24 | TT | 3 | 58 | 75 | 3 | 25 | 24 | 53141 | 0 |

| TT-3-58-100-25-24 | TT | 3 | 58 | 100 | 4 | 25 | 24 | 64738 | 0 |

| TT-3-58-30-30-24 | TT | 3 | 58 | 30 | 1 | 30 | 24 | 30643 | 0 |

| TT-3-58-60-30-24 | TT | 3 | 58 | 60 | 2 | 30 | 24 | 42939 | 0 |

| TT-3-58-90-30-24 | TT | 3 | 58 | 90 | 3 | 30 | 24 | 55235 | 0 |

| TT-3-58-120-30-24 | TT | 3 | 58 | 120 | 4 | 30 | 24 | 67530 | 0 |

| TT-5-18-20-20-20 | TT | 5 | 18 | 20 | 1 | 20 | 20 | 11641 | 0 |

| TT-5-18-40-20-20 | TT | 5 | 18 | 40 | 2 | 20 | 20 | 16533 | 0 |

| TT-5-18-60-20-20 | TT | 5 | 18 | 60 | 3 | 20 | 20 | 21424 | 0 |

| TT-5-18-80-20-20 | TT | 5 | 18 | 80 | 4 | 20 | 20 | 26315 | 0 |

| TT-5-18-25-25-20 | TT | 5 | 18 | 25 | 1 | 25 | 20 | 12306 | 0 |

| TT-5-18-50-25-20 | TT | 5 | 18 | 50 | 2 | 25 | 20 | 17863 | 0 |

| TT-5-18-75-25-20 | TT | 5 | 18 | 75 | 3 | 25 | 20 | 23419 | 0 |

| TT-5-18-100-25-20 | TT | 5 | 18 | 100 | 4 | 25 | 20 | 28975 | 0 |

| TT-5-18-30-30-20 | TT | 5 | 18 | 30 | 1 | 30 | 20 | 13079 | 0 |

| TT-5-18-60-30-20 | TT | 5 | 18 | 60 | 2 | 30 | 20 | 19409 | 0 |

| TT-5-18-90-30-20 | TT | 5 | 18 | 90 | 3 | 30 | 20 | 25738 | 0 |

| TT-5-18-120-30-20 | TT | 5 | 18 | 120 | 4 | 30 | 20 | 32067 | 0 |

| TT-5-18-20-20-24 | TT | 5 | 18 | 20 | 1 | 20 | 24 | 13323 | 0 |

| TT-5-18-40-20-24 | TT | 5 | 18 | 40 | 2 | 20 | 24 | 19055 | 0 |

| TT-5-18-60-20-24 | TT | 5 | 18 | 60 | 3 | 20 | 24 | 24787 | 0 |

| TT-5-18-80-20-24 | TT | 5 | 18 | 80 | 4 | 20 | 24 | 30520 | 0 |

| TT-5-18-25-25-24 | TT | 5 | 18 | 25 | 1 | 25 | 24 | 13988 | 0 |

| TT-5-18-50-25-24 | TT | 5 | 18 | 50 | 2 | 25 | 24 | 20385 | 0 |

| TT-5-18-75-25-24 | TT | 5 | 18 | 75 | 3 | 25 | 24 | 26782 | 0 |

| TT-5-18-100-25-24 | TT | 5 | 18 | 100 | 4 | 25 | 24 | 33180 | 0 |

| TT-5-18-30-30-24 | TT | 5 | 18 | 30 | 1 | 30 | 24 | 14761 | 0 |

| TT-5-18-60-30-24 | TT | 5 | 18 | 60 | 2 | 30 | 24 | 21931 | 0 |

| TT-5-18-90-30-24 | TT | 5 | 18 | 90 | 3 | 30 | 24 | 29101 | 0 |

| TT-5-18-120-30-24 | TT | 5 | 18 | 120 | 4 | 30 | 24 | 36272 | 0 |

| TT-5-28-20-20-20 | TT | 5 | 28 | 20 | 1 | 20 | 20 | 13860 | 0 |

| TT-5-28-40-20-20 | TT | 5 | 28 | 40 | 2 | 20 | 20 | 19297 | 0 |

| TT-5-28-60-20-20 | TT | 5 | 28 | 60 | 3 | 20 | 20 | 24735 | 0 |

| TT-5-28-80-20-20 | TT | 5 | 28 | 80 | 4 | 20 | 20 | 30172 | 0 |

| TT-5-28-25-25-20 | TT | 5 | 28 | 25 | 1 | 25 | 20 | 14525 | 0 |

| TT-5-28-50-25-20 | TT | 5 | 28 | 50 | 2 | 25 | 20 | 20627 | 0 |

| TT-5-28-75-25-20 | TT | 5 | 28 | 75 | 3 | 25 | 20 | 26730 | 0 |

| TT-5-28-100-25-20 | TT | 5 | 28 | 100 | 4 | 25 | 20 | 32832 | 0 |

| TT-5-28-30-30-20 | TT | 5 | 28 | 30 | 1 | 30 | 20 | 15298 | 0 |

| TT-5-28-60-30-20 | TT | 5 | 28 | 60 | 2 | 30 | 20 | 22173 | 0 |

| TT-5-28-90-30-20 | TT | 5 | 28 | 90 | 3 | 30 | 20 | 29049 | 0 |

| TT-5-28-120-30-20 | TT | 5 | 28 | 120 | 4 | 30 | 20 | 35924 | 0 |

| TT-5-28-20-20-24 | TT | 5 | 28 | 20 | 1 | 20 | 24 | 15764 | 0 |

| TT-5-28-40-20-24 | TT | 5 | 28 | 40 | 2 | 20 | 24 | 22154 | 0 |

| TT-5-28-60-20-24 | TT | 5 | 28 | 60 | 3 | 20 | 24 | 28544 | 0 |

| TT-5-28-80-20-24 | TT | 5 | 28 | 80 | 4 | 20 | 24 | 34934 | 0 |

| TT-5-28-25-25-24 | TT | 5 | 28 | 25 | 1 | 25 | 24 | 16429 | 0 |

| TT-5-28-50-25-24 | TT | 5 | 28 | 50 | 2 | 25 | 24 | 23484 | 0 |

| TT-5-28-75-25-24 | TT | 5 | 28 | 75 | 3 | 25 | 24 | 30539 | 0 |

| TT-5-28-100-25-24 | TT | 5 | 28 | 100 | 4 | 25 | 24 | 37594 | 0 |

| TT-5-28-30-30-24 | TT | 5 | 28 | 30 | 1 | 30 | 24 | 17202 | 0 |

| TT-5-28-60-30-24 | TT | 5 | 28 | 60 | 2 | 30 | 24 | 25030 | 0 |

| TT-5-28-90-30-24 | TT | 5 | 28 | 90 | 3 | 30 | 24 | 32858 | 0 |

| TT-5-28-120-30-24 | TT | 5 | 28 | 120 | 4 | 30 | 24 | 40686 | 0 |

| TT-5-38-20-20-20 | TT | 5 | 38 | 20 | 1 | 20 | 20 | 15733 | 0 |

| TT-5-38-40-20-20 | TT | 5 | 38 | 40 | 2 | 20 | 20 | 21463 | 0 |

| TT-5-38-60-20-20 | TT | 5 | 38 | 60 | 3 | 20 | 20 | 27193 | 0 |

| TT-5-38-80-20-20 | TT | 5 | 38 | 80 | 4 | 20 | 20 | 32924 | 0 |

| TT-5-38-25-25-20 | TT | 5 | 38 | 25 | 1 | 25 | 20 | 16398 | 0 |

| TT-5-38-50-25-20 | TT | 5 | 38 | 50 | 2 | 25 | 20 | 22793 | 0 |

| TT-5-38-75-25-20 | TT | 5 | 38 | 75 | 3 | 25 | 20 | 29188 | 0 |

| TT-5-38-100-25-20 | TT | 5 | 38 | 100 | 4 | 25 | 20 | 35584 | 0 |

| TT-5-38-30-30-20 | TT | 5 | 38 | 30 | 1 | 30 | 20 | 17171 | 0 |

| TT-5-38-60-30-20 | TT | 5 | 38 | 60 | 2 | 30 | 20 | 24339 | 0 |

| TT-5-38-90-30-20 | TT | 5 | 38 | 90 | 3 | 30 | 20 | 31507 | 0 |

| TT-5-38-120-30-20 | TT | 5 | 38 | 120 | 4 | 30 | 20 | 38676 | 0 |

| TT-5-38-20-20-24 | TT | 5 | 38 | 20 | 1 | 20 | 24 | 16255 | 0 |

| TT-5-38-40-20-24 | TT | 5 | 38 | 40 | 2 | 20 | 24 | 22246 | 0 |

| TT-5-38-60-20-24 | TT | 5 | 38 | 60 | 3 | 20 | 24 | 28237 | 0 |

| TT-5-38-80-20-24 | TT | 5 | 38 | 80 | 4 | 20 | 24 | 34228 | 0 |

| TT-5-38-25-25-24 | TT | 5 | 38 | 25 | 1 | 25 | 24 | 16920 | 0 |

| TT-5-38-50-25-24 | TT | 5 | 38 | 50 | 2 | 25 | 24 | 23576 | 0 |

| TT-5-38-75-25-24 | TT | 5 | 38 | 75 | 3 | 25 | 24 | 30232 | 0 |

| TT-5-38-100-25-24 | TT | 5 | 38 | 100 | 4 | 25 | 24 | 36888 | 0 |

| TT-5-38-30-30-24 | TT | 5 | 38 | 30 | 1 | 30 | 24 | 17693 | 0 |

| TT-5-38-60-30-24 | TT | 5 | 38 | 60 | 2 | 30 | 24 | 25122 | 0 |

| TT-5-38-90-30-24 | TT | 5 | 38 | 90 | 3 | 30 | 24 | 32551 | 0 |

| TT-5-38-120-30-24 | TT | 5 | 38 | 120 | 4 | 30 | 24 | 39980 | 0 |

| TT-5-46-20-20-20 | TT | 5 | 46 | 20 | 1 | 20 | 20 | 18212 | 0 |

| TT-5-46-40-20-20 | TT | 5 | 46 | 40 | 2 | 20 | 20 | 24203 | 0 |

| TT-5-46-60-20-20 | TT | 5 | 46 | 60 | 3 | 20 | 20 | 30194 | 0 |

| TT-5-46-80-20-20 | TT | 5 | 46 | 80 | 4 | 20 | 20 | 36185 | 0 |

| TT-5-46-25-25-20 | TT | 5 | 46 | 25 | 1 | 25 | 20 | 18877 | 0 |

| TT-5-46-50-25-20 | TT | 5 | 46 | 50 | 2 | 25 | 20 | 25533 | 0 |

| TT-5-46-75-25-20 | TT | 5 | 46 | 75 | 3 | 25 | 20 | 32189 | 0 |

| TT-5-46-100-25-20 | TT | 5 | 46 | 100 | 4 | 25 | 20 | 38845 | 0 |

| TT-5-46-30-30-20 | TT | 5 | 46 | 30 | 1 | 30 | 20 | 19650 | 0 |

| TT-5-46-60-30-20 | TT | 5 | 46 | 60 | 2 | 30 | 20 | 27079 | 0 |

| TT-5-46-90-30-20 | TT | 5 | 46 | 90 | 3 | 30 | 20 | 34508 | 0 |

| TT-5-46-120-30-20 | TT | 5 | 46 | 120 | 4 | 30 | 20 | 41937 | 0 |

| TT-5-46-20-20-24 | TT | 5 | 46 | 20 | 1 | 20 | 24 | 18758 | 0 |

| TT-5-46-40-20-24 | TT | 5 | 46 | 40 | 2 | 20 | 24 | 25022 | 0 |

| TT-5-46-60-20-24 | TT | 5 | 46 | 60 | 3 | 20 | 24 | 31285 | 0 |

| TT-5-46-80-20-24 | TT | 5 | 46 | 80 | 4 | 20 | 24 | 37549 | 0 |

| TT-5-46-25-25-24 | TT | 5 | 46 | 25 | 1 | 25 | 24 | 19423 | 0 |

| TT-5-46-50-25-24 | TT | 5 | 46 | 50 | 2 | 25 | 24 | 26352 | 0 |

| TT-5-46-75-25-24 | TT | 5 | 46 | 75 | 3 | 25 | 24 | 33280 | 0 |

| TT-5-46-100-25-24 | TT | 5 | 46 | 100 | 4 | 25 | 24 | 40209 | 0 |

| TT-5-46-30-30-24 | TT | 5 | 46 | 30 | 1 | 30 | 24 | 20196 | 0 |

| TT-5-46-60-30-24 | TT | 5 | 46 | 60 | 2 | 30 | 24 | 27898 | 0 |

| TT-5-46-90-30-24 | TT | 5 | 46 | 90 | 3 | 30 | 24 | 35599 | 0 |

| TT-5-46-120-30-24 | TT | 5 | 46 | 120 | 4 | 30 | 24 | 43301 | 0 |

| TT-5-58-20-20-20 | TT | 5 | 58 | 20 | 1 | 20 | 20 | 29777 | 0 |

| TT-5-58-40-20-20 | TT | 5 | 58 | 40 | 2 | 20 | 20 | 40329 | 0 |

| TT-5-58-60-20-20 | TT | 5 | 58 | 60 | 3 | 20 | 20 | 50880 | 0 |

| TT-5-58-80-20-20 | TT | 5 | 58 | 80 | 4 | 20 | 20 | 61431 | 0 |

| TT-5-58-25-25-20 | TT | 5 | 58 | 25 | 1 | 25 | 20 | 30442 | 0 |

| TT-5-58-50-25-20 | TT | 5 | 58 | 50 | 2 | 25 | 20 | 41659 | 0 |

| TT-5-58-75-25-20 | TT | 5 | 58 | 75 | 3 | 25 | 20 | 52875 | 0 |

| TT-5-58-100-25-20 | TT | 5 | 58 | 100 | 4 | 25 | 20 | 64091 | 0 |

| TT-5-58-30-30-20 | TT | 5 | 58 | 30 | 1 | 30 | 20 | 31215 | 0 |

| TT-5-58-60-30-20 | TT | 5 | 58 | 60 | 2 | 30 | 20 | 43205 | 0 |

| TT-5-58-90-30-20 | TT | 5 | 58 | 90 | 3 | 30 | 20 | 55194 | 0 |

| TT-5-58-120-30-20 | TT | 5 | 58 | 120 | 4 | 30 | 20 | 67183 | 0 |

| TT-5-58-20-20-24 | TT | 5 | 58 | 20 | 1 | 20 | 24 | 30870 | 0 |

| TT-5-58-40-20-24 | TT | 5 | 58 | 40 | 2 | 20 | 24 | 41968 | 0 |

| TT-5-58-60-20-24 | TT | 5 | 58 | 60 | 3 | 20 | 24 | 53065 | 0 |

| TT-5-58-80-20-24 | TT | 5 | 58 | 80 | 4 | 20 | 24 | 64163 | 0 |

| TT-5-58-25-25-24 | TT | 5 | 58 | 25 | 1 | 25 | 24 | 31535 | 0 |

| TT-5-58-50-25-24 | TT | 5 | 58 | 50 | 2 | 25 | 24 | 43298 | 0 |

| TT-5-58-75-25-24 | TT | 5 | 58 | 75 | 3 | 25 | 24 | 55060 | 0 |

| TT-5-58-100-25-24 | TT | 5 | 58 | 100 | 4 | 25 | 24 | 66823 | 0 |

| TT-5-58-30-30-24 | TT | 5 | 58 | 30 | 1 | 30 | 24 | 32308 | 0 |

| TT-5-58-60-30-24 | TT | 5 | 58 | 60 | 2 | 30 | 24 | 44844 | 0 |

| TT-5-58-90-30-24 | TT | 5 | 58 | 90 | 3 | 30 | 24 | 57379 | 0 |

| TT-5-58-120-30-24 | TT | 5 | 58 | 120 | 4 | 30 | 24 | 69915 | 0 |

| TT-7.5-18-20-20-20 | TT | 7.5 | 18 | 20 | 1 | 20 | 20 | 13674 | 0 |

| TT-7.5-18-40-20-20 | TT | 7.5 | 18 | 40 | 2 | 20 | 20 | 18697 | 0 |

| TT-7.5-18-60-20-20 | TT | 7.5 | 18 | 60 | 3 | 20 | 20 | 23721 | 0 |

| TT-7.5-18-80-20-20 | TT | 7.5 | 18 | 80 | 4 | 20 | 20 | 28744 | 0 |

| TT-7.5-18-25-25-20 | TT | 7.5 | 18 | 25 | 1 | 25 | 20 | 14907 | 0 |

| TT-7.5-18-50-25-20 | TT | 7.5 | 18 | 50 | 2 | 25 | 20 | 21163 | 0 |

| TT-7.5-18-75-25-20 | TT | 7.5 | 18 | 75 | 3 | 25 | 20 | 27420 | 0 |

| TT-7.5-18-100-25-20 | TT | 7.5 | 18 | 100 | 4 | 25 | 20 | 33676 | 0 |

| TT-7.5-18-30-30-20 | TT | 7.5 | 18 | 30 | 1 | 30 | 20 | 16324 | 0 |

| TT-7.5-18-60-30-20 | TT | 7.5 | 18 | 60 | 2 | 30 | 20 | 23997 | 0 |

| TT-7.5-18-90-30-20 | TT | 7.5 | 18 | 90 | 3 | 30 | 20 | 31671 | 0 |

| TT-7.5-18-120-30-20 | TT | 7.5 | 18 | 120 | 4 | 30 | 20 | 39344 | 0 |

| TT-7.5-18-20-20-24 | TT | 7.5 | 18 | 20 | 1 | 20 | 24 | 15356 | 0 |

| TT-7.5-18-40-20-24 | TT | 7.5 | 18 | 40 | 2 | 20 | 24 | 21220 | 0 |

| TT-7.5-18-60-20-24 | TT | 7.5 | 18 | 60 | 3 | 20 | 24 | 27084 | 0 |

| TT-7.5-18-80-20-24 | TT | 7.5 | 18 | 80 | 4 | 20 | 24 | 32948 | 0 |

| TT-7.5-18-25-25-24 | TT | 7.5 | 18 | 25 | 1 | 25 | 24 | 16589 | 0 |

| TT-7.5-18-50-25-24 | TT | 7.5 | 18 | 50 | 2 | 25 | 24 | 23686 | 0 |

| TT-7.5-18-75-25-24 | TT | 7.5 | 18 | 75 | 3 | 25 | 24 | 30783 | 0 |

| TT-7.5-18-100-25-24 | TT | 7.5 | 18 | 100 | 4 | 25 | 24 | 37880 | 0 |

| TT-7.5-18-30-30-24 | TT | 7.5 | 18 | 30 | 1 | 30 | 24 | 18006 | 0 |

| TT-7.5-18-60-30-24 | TT | 7.5 | 18 | 60 | 2 | 30 | 24 | 26520 | 0 |

| TT-7.5-18-90-30-24 | TT | 7.5 | 18 | 90 | 3 | 30 | 24 | 35034 | 0 |

| TT-7.5-18-120-30-24 | TT | 7.5 | 18 | 120 | 4 | 30 | 24 | 43548 | 0 |

| TT-7.5-28-20-20-20 | TT | 7.5 | 28 | 20 | 1 | 20 | 20 | 16072 | 0 |

| TT-7.5-28-40-20-20 | TT | 7.5 | 28 | 40 | 2 | 20 | 20 | 21602 | 0 |

| TT-7.5-28-60-20-20 | TT | 7.5 | 28 | 60 | 3 | 20 | 20 | 27131 | 0 |

| TT-7.5-28-80-20-20 | TT | 7.5 | 28 | 80 | 4 | 20 | 20 | 32661 | 0 |

| TT-7.5-28-25-25-20 | TT | 7.5 | 28 | 25 | 1 | 25 | 20 | 17305 | 0 |

| TT-7.5-28-50-25-20 | TT | 7.5 | 28 | 50 | 2 | 25 | 20 | 24068 | 0 |

| TT-7.5-28-75-25-20 | TT | 7.5 | 28 | 75 | 3 | 25 | 20 | 30830 | 0 |

| TT-7.5-28-100-25-20 | TT | 7.5 | 28 | 100 | 4 | 25 | 20 | 37593 | 0 |

| TT-7.5-28-30-30-20 | TT | 7.5 | 28 | 30 | 1 | 30 | 20 | 18722 | 0 |

| TT-7.5-28-60-30-20 | TT | 7.5 | 28 | 60 | 2 | 30 | 20 | 26902 | 0 |

| TT-7.5-28-90-30-20 | TT | 7.5 | 28 | 90 | 3 | 30 | 20 | 35081 | 0 |

| TT-7.5-28-120-30-20 | TT | 7.5 | 28 | 120 | 4 | 30 | 20 | 43261 | 0 |

| TT-7.5-28-20-20-24 | TT | 7.5 | 28 | 20 | 1 | 20 | 24 | 17846 | 0 |

| TT-7.5-28-40-20-24 | TT | 7.5 | 28 | 40 | 2 | 20 | 24 | 24262 | 0 |

| TT-7.5-28-60-20-24 | TT | 7.5 | 28 | 60 | 3 | 20 | 24 | 30678 | 0 |

| TT-7.5-28-80-20-24 | TT | 7.5 | 28 | 80 | 4 | 20 | 24 | 37095 | 0 |

| TT-7.5-28-25-25-24 | TT | 7.5 | 28 | 25 | 1 | 25 | 24 | 19079 | 0 |

| TT-7.5-28-50-25-24 | TT | 7.5 | 28 | 50 | 2 | 25 | 24 | 26728 | 0 |

| TT-7.5-28-75-25-24 | TT | 7.5 | 28 | 75 | 3 | 25 | 24 | 34377 | 0 |

| TT-7.5-28-100-25-24 | TT | 7.5 | 28 | 100 | 4 | 25 | 24 | 42027 | 0 |

| TT-7.5-28-30-30-24 | TT | 7.5 | 28 | 30 | 1 | 30 | 24 | 20496 | 0 |

| TT-7.5-28-60-30-24 | TT | 7.5 | 28 | 60 | 2 | 30 | 24 | 29562 | 0 |

| TT-7.5-28-90-30-24 | TT | 7.5 | 28 | 90 | 3 | 30 | 24 | 38628 | 0 |

| TT-7.5-28-120-30-24 | TT | 7.5 | 28 | 120 | 4 | 30 | 24 | 47695 | 0 |

| TT-7.5-38-20-20-20 | TT | 7.5 | 38 | 20 | 1 | 20 | 20 | 20526 | 0 |

| TT-7.5-38-40-20-20 | TT | 7.5 | 38 | 40 | 2 | 20 | 20 | 27617 | 0 |

| TT-7.5-38-60-20-20 | TT | 7.5 | 38 | 60 | 3 | 20 | 20 | 34709 | 0 |

| TT-7.5-38-80-20-20 | TT | 7.5 | 38 | 80 | 4 | 20 | 20 | 41801 | 0 |

| TT-7.5-38-25-25-20 | TT | 7.5 | 38 | 25 | 1 | 25 | 20 | 21759 | 0 |

| TT-7.5-38-50-25-20 | TT | 7.5 | 38 | 50 | 2 | 25 | 20 | 30083 | 0 |

| TT-7.5-38-75-25-20 | TT | 7.5 | 38 | 75 | 3 | 25 | 20 | 38408 | 0 |

| TT-7.5-38-100-25-20 | TT | 7.5 | 38 | 100 | 4 | 25 | 20 | 46733 | 0 |

| TT-7.5-38-30-30-20 | TT | 7.5 | 38 | 30 | 1 | 30 | 20 | 23176 | 0 |

| TT-7.5-38-60-30-20 | TT | 7.5 | 38 | 60 | 2 | 30 | 20 | 32917 | 0 |

| TT-7.5-38-90-30-20 | TT | 7.5 | 38 | 90 | 3 | 30 | 20 | 42659 | 0 |

| TT-7.5-38-120-30-20 | TT | 7.5 | 38 | 120 | 4 | 30 | 20 | 52401 | 0 |

| TT-7.5-38-20-20-24 | TT | 7.5 | 38 | 20 | 1 | 20 | 24 | 21315 | 0 |

| TT-7.5-38-40-20-24 | TT | 7.5 | 38 | 40 | 2 | 20 | 24 | 28801 | 0 |

| TT-7.5-38-60-20-24 | TT | 7.5 | 38 | 60 | 3 | 20 | 24 | 36287 | 0 |

| TT-7.5-38-80-20-24 | TT | 7.5 | 38 | 80 | 4 | 20 | 24 | 43774 | 0 |

| TT-7.5-38-25-25-24 | TT | 7.5 | 38 | 25 | 1 | 25 | 24 | 22548 | 0 |

| TT-7.5-38-50-25-24 | TT | 7.5 | 38 | 50 | 2 | 25 | 24 | 31267 | 0 |

| TT-7.5-38-75-25-24 | TT | 7.5 | 38 | 75 | 3 | 25 | 24 | 39986 | 0 |

| TT-7.5-38-100-25-24 | TT | 7.5 | 38 | 100 | 4 | 25 | 24 | 48706 | 0 |

| TT-7.5-38-30-30-24 | TT | 7.5 | 38 | 30 | 1 | 30 | 24 | 23965 | 0 |

| TT-7.5-38-60-30-24 | TT | 7.5 | 38 | 60 | 2 | 30 | 24 | 34101 | 0 |

| TT-7.5-38-90-30-24 | TT | 7.5 | 38 | 90 | 3 | 30 | 24 | 44237 | 0 |

| TT-7.5-38-120-30-24 | TT | 7.5 | 38 | 120 | 4 | 30 | 24 | 54374 | 0 |

| TT-7.5-46-20-20-20 | TT | 7.5 | 46 | 20 | 1 | 20 | 20 | 24318 | 0 |

| TT-7.5-46-40-20-20 | TT | 7.5 | 46 | 40 | 2 | 20 | 20 | 31804 | 0 |

| TT-7.5-46-60-20-20 | TT | 7.5 | 46 | 60 | 3 | 20 | 20 | 39290 | 0 |

| TT-7.5-46-80-20-20 | TT | 7.5 | 46 | 80 | 4 | 20 | 20 | 46776 | 0 |

| TT-7.5-46-25-25-20 | TT | 7.5 | 46 | 25 | 1 | 25 | 20 | 25551 | 0 |

| TT-7.5-46-50-25-20 | TT | 7.5 | 46 | 50 | 2 | 25 | 20 | 34270 | 0 |

| TT-7.5-46-75-25-20 | TT | 7.5 | 46 | 75 | 3 | 25 | 20 | 42989 | 0 |

| TT-7.5-46-100-25-20 | TT | 7.5 | 46 | 100 | 4 | 25 | 20 | 51708 | 0 |

| TT-7.5-46-30-30-20 | TT | 7.5 | 46 | 30 | 1 | 30 | 20 | 26968 | 0 |

| TT-7.5-46-60-30-20 | TT | 7.5 | 46 | 60 | 2 | 30 | 20 | 37104 | 0 |

| TT-7.5-46-90-30-20 | TT | 7.5 | 46 | 90 | 3 | 30 | 20 | 47240 | 0 |

| TT-7.5-46-120-30-20 | TT | 7.5 | 46 | 120 | 4 | 30 | 20 | 57376 | 0 |

| TT-7.5-46-20-20-24 | TT | 7.5 | 46 | 20 | 1 | 20 | 24 | 25083 | 0 |

| TT-7.5-46-40-20-24 | TT | 7.5 | 46 | 40 | 2 | 20 | 24 | 32952 | 0 |

| TT-7.5-46-60-20-24 | TT | 7.5 | 46 | 60 | 3 | 20 | 24 | 40820 | 0 |

| TT-7.5-46-80-20-24 | TT | 7.5 | 46 | 80 | 4 | 20 | 24 | 48689 | 0 |

| TT-7.5-46-25-25-24 | TT | 7.5 | 46 | 25 | 1 | 25 | 24 | 26316 | 0 |

| TT-7.5-46-50-25-24 | TT | 7.5 | 46 | 50 | 2 | 25 | 24 | 35418 | 0 |

| TT-7.5-46-75-25-24 | TT | 7.5 | 46 | 75 | 3 | 25 | 24 | 44519 | 0 |

| TT-7.5-46-100-25-24 | TT | 7.5 | 46 | 100 | 4 | 25 | 24 | 53621 | 0 |

| TT-7.5-46-30-30-24 | TT | 7.5 | 46 | 30 | 1 | 30 | 24 | 27733 | 0 |

| TT-7.5-46-60-30-24 | TT | 7.5 | 46 | 60 | 2 | 30 | 24 | 38252 | 0 |

| TT-7.5-46-90-30-24 | TT | 7.5 | 46 | 90 | 3 | 30 | 24 | 48770 | 0 |

| TT-7.5-46-120-30-24 | TT | 7.5 | 46 | 120 | 4 | 30 | 24 | 59289 | 0 |

| TT-7.5-58-20-20-20 | TT | 7.5 | 58 | 20 | 1 | 20 | 20 | 33379 | 0 |

| TT-7.5-58-40-20-20 | TT | 7.5 | 58 | 40 | 2 | 20 | 20 | 44062 | 0 |

| TT-7.5-58-60-20-20 | TT | 7.5 | 58 | 60 | 3 | 20 | 20 | 54745 | 0 |

| TT-7.5-58-80-20-20 | TT | 7.5 | 58 | 80 | 4 | 20 | 20 | 65429 | 0 |

| TT-7.5-58-25-25-20 | TT | 7.5 | 58 | 25 | 1 | 25 | 20 | 34612 | 0 |

| TT-7.5-58-50-25-20 | TT | 7.5 | 58 | 50 | 2 | 25 | 20 | 46528 | 0 |

| TT-7.5-58-75-25-20 | TT | 7.5 | 58 | 75 | 3 | 25 | 20 | 58444 | 0 |

| TT-7.5-58-100-25-20 | TT | 7.5 | 58 | 100 | 4 | 25 | 20 | 70361 | 0 |

| TT-7.5-58-30-30-20 | TT | 7.5 | 58 | 30 | 1 | 30 | 20 | 36029 | 0 |

| TT-7.5-58-60-30-20 | TT | 7.5 | 58 | 60 | 2 | 30 | 20 | 49362 | 0 |

| TT-7.5-58-90-30-20 | TT | 7.5 | 58 | 90 | 3 | 30 | 20 | 62695 | 0 |

| TT-7.5-58-120-30-20 | TT | 7.5 | 58 | 120 | 4 | 30 | 20 | 76029 | 0 |

| TT-7.5-58-20-20-24 | TT | 7.5 | 58 | 20 | 1 | 20 | 24 | 34471 | 0 |

| TT-7.5-58-40-20-24 | TT | 7.5 | 58 | 40 | 2 | 20 | 24 | 45701 | 0 |

| TT-7.5-58-60-20-24 | TT | 7.5 | 58 | 60 | 3 | 20 | 24 | 56931 | 0 |

| TT-7.5-58-80-20-24 | TT | 7.5 | 58 | 80 | 4 | 20 | 24 | 68160 | 0 |

| TT-7.5-58-25-25-24 | TT | 7.5 | 58 | 25 | 1 | 25 | 24 | 35704 | 0 |

| TT-7.5-58-50-25-24 | TT | 7.5 | 58 | 50 | 2 | 25 | 24 | 48167 | 0 |

| TT-7.5-58-75-25-24 | TT | 7.5 | 58 | 75 | 3 | 25 | 24 | 60630 | 0 |

| TT-7.5-58-100-25-24 | TT | 7.5 | 58 | 100 | 4 | 25 | 24 | 73092 | 0 |

| TT-7.5-58-30-30-24 | TT | 7.5 | 58 | 30 | 1 | 30 | 24 | 37121 | 0 |

| TT-7.5-58-60-30-24 | TT | 7.5 | 58 | 60 | 2 | 30 | 24 | 51001 | 0 |

| TT-7.5-58-90-30-24 | TT | 7.5 | 58 | 90 | 3 | 30 | 24 | 64881 | 0 |

| TT-7.5-58-120-30-24 | TT | 7.5 | 58 | 120 | 4 | 30 | 24 | 78760 | 0 |

| TT-10-18-20-20-20 | TT | 10 | 18 | 20 | 1 | 20 | 20 | 16911 | 0 |

| TT-10-18-40-20-20 | TT | 10 | 18 | 40 | 2 | 20 | 20 | 23280 | 0 |

| TT-10-18-60-20-20 | TT | 10 | 18 | 60 | 3 | 20 | 20 | 29650 | 0 |

| TT-10-18-80-20-20 | TT | 10 | 18 | 80 | 4 | 20 | 20 | 36020 | 0 |

| TT-10-18-25-25-20 | TT | 10 | 18 | 25 | 1 | 25 | 20 | 18144 | 0 |

| TT-10-18-50-25-20 | TT | 10 | 18 | 50 | 2 | 25 | 20 | 25746 | 0 |

| TT-10-18-75-25-20 | TT | 10 | 18 | 75 | 3 | 25 | 20 | 33349 | 0 |

| TT-10-18-100-25-20 | TT | 10 | 18 | 100 | 4 | 25 | 20 | 40952 | 0 |

| TT-10-18-30-30-20 | TT | 10 | 18 | 30 | 1 | 30 | 20 | 19561 | 0 |

| TT-10-18-60-30-20 | TT | 10 | 18 | 60 | 2 | 30 | 20 | 28580 | 0 |

| TT-10-18-90-30-20 | TT | 10 | 18 | 90 | 3 | 30 | 20 | 37600 | 0 |

| TT-10-18-120-30-20 | TT | 10 | 18 | 120 | 4 | 30 | 20 | 46620 | 0 |

| TT-10-18-20-20-24 | TT | 10 | 18 | 20 | 1 | 20 | 24 | 17740 | 0 |

| TT-10-18-40-20-24 | TT | 10 | 18 | 40 | 2 | 20 | 24 | 24525 | 0 |

| TT-10-18-60-20-24 | TT | 10 | 18 | 60 | 3 | 20 | 24 | 31310 | 0 |

| TT-10-18-80-20-24 | TT | 10 | 18 | 80 | 4 | 20 | 24 | 38095 | 0 |

| TT-10-18-25-25-24 | TT | 10 | 18 | 25 | 1 | 25 | 24 | 18973 | 0 |

| TT-10-18-50-25-24 | TT | 10 | 18 | 50 | 2 | 25 | 24 | 26991 | 0 |

| TT-10-18-75-25-24 | TT | 10 | 18 | 75 | 3 | 25 | 24 | 35009 | 0 |

| TT-10-18-100-25-24 | TT | 10 | 18 | 100 | 4 | 25 | 24 | 43027 | 0 |

| TT-10-18-30-30-24 | TT | 10 | 18 | 30 | 1 | 30 | 24 | 20390 | 0 |

| TT-10-18-60-30-24 | TT | 10 | 18 | 60 | 2 | 30 | 24 | 29825 | 0 |

| TT-10-18-90-30-24 | TT | 10 | 18 | 90 | 3 | 30 | 24 | 39260 | 0 |

| TT-10-18-120-30-24 | TT | 10 | 18 | 120 | 4 | 30 | 24 | 48695 | 0 |

| TT-10-28-20-20-20 | TT | 10 | 28 | 20 | 1 | 20 | 20 | 17972 | 0 |

| TT-10-28-40-20-20 | TT | 10 | 28 | 40 | 2 | 20 | 20 | 24341 | 0 |

| TT-10-28-60-20-20 | TT | 10 | 28 | 60 | 3 | 20 | 20 | 30711 | 0 |

| TT-10-28-80-20-20 | TT | 10 | 28 | 80 | 4 | 20 | 20 | 37081 | 0 |

| TT-10-28-25-25-20 | TT | 10 | 28 | 25 | 1 | 25 | 20 | 19205 | 0 |

| TT-10-28-50-25-20 | TT | 10 | 28 | 50 | 2 | 25 | 20 | 26807 | 0 |

| TT-10-28-75-25-20 | TT | 10 | 28 | 75 | 3 | 25 | 20 | 34410 | 0 |

| TT-10-28-100-25-20 | TT | 10 | 28 | 100 | 4 | 25 | 20 | 42013 | 0 |

| TT-10-28-30-30-20 | TT | 10 | 28 | 30 | 1 | 30 | 20 | 20622 | 0 |

| TT-10-28-60-30-20 | TT | 10 | 28 | 60 | 2 | 30 | 20 | 29641 | 0 |

| TT-10-28-90-30-20 | TT | 10 | 28 | 90 | 3 | 30 | 20 | 38661 | 0 |

| TT-10-28-120-30-20 | TT | 10 | 28 | 120 | 4 | 30 | 20 | 47681 | 0 |

| TT-10-28-20-20-24 | TT | 10 | 28 | 20 | 1 | 20 | 24 | 20150 | 0 |

| TT-10-28-40-20-24 | TT | 10 | 28 | 40 | 2 | 20 | 24 | 27609 | 0 |

| TT-10-28-60-20-24 | TT | 10 | 28 | 60 | 3 | 20 | 24 | 35069 | 0 |

| TT-10-28-80-20-24 | TT | 10 | 28 | 80 | 4 | 20 | 24 | 42528 | 0 |

| TT-10-28-25-25-24 | TT | 10 | 28 | 25 | 1 | 25 | 24 | 21383 | 0 |

| TT-10-28-50-25-24 | TT | 10 | 28 | 50 | 2 | 25 | 24 | 30075 | 0 |

| TT-10-28-75-25-24 | TT | 10 | 28 | 75 | 3 | 25 | 24 | 38768 | 0 |

| TT-10-28-100-25-24 | TT | 10 | 28 | 100 | 4 | 25 | 24 | 47460 | 0 |

| TT-10-28-30-30-24 | TT | 10 | 28 | 30 | 1 | 30 | 24 | 22800 | 0 |

| TT-10-28-60-30-24 | TT | 10 | 28 | 60 | 2 | 30 | 24 | 32909 | 0 |

| TT-10-28-90-30-24 | TT | 10 | 28 | 90 | 3 | 30 | 24 | 43019 | 0 |

| TT-10-28-120-30-24 | TT | 10 | 28 | 120 | 4 | 30 | 24 | 53128 | 0 |

| TT-10-38-20-20-20 | TT | 10 | 38 | 20 | 1 | 20 | 20 | 21650 | 0 |

| TT-10-38-40-20-20 | TT | 10 | 38 | 40 | 2 | 20 | 20 | 28826 | 0 |

| TT-10-38-60-20-20 | TT | 10 | 38 | 60 | 3 | 20 | 20 | 36001 | 0 |

| TT-10-38-80-20-20 | TT | 10 | 38 | 80 | 4 | 20 | 20 | 43177 | 0 |

| TT-10-38-25-25-20 | TT | 10 | 38 | 25 | 1 | 25 | 20 | 22883 | 0 |

| TT-10-38-50-25-20 | TT | 10 | 38 | 50 | 2 | 25 | 20 | 31292 | 0 |

| TT-10-38-75-25-20 | TT | 10 | 38 | 75 | 3 | 25 | 20 | 39700 | 0 |

| TT-10-38-100-25-20 | TT | 10 | 38 | 100 | 4 | 25 | 20 | 48109 | 0 |

| TT-10-38-30-30-20 | TT | 10 | 38 | 30 | 1 | 30 | 20 | 24300 | 0 |

| TT-10-38-60-30-20 | TT | 10 | 38 | 60 | 2 | 30 | 20 | 34126 | 0 |

| TT-10-38-90-30-20 | TT | 10 | 38 | 90 | 3 | 30 | 20 | 43951 | 0 |

| TT-10-38-120-30-20 | TT | 10 | 38 | 120 | 4 | 30 | 20 | 53777 | 0 |

| TT-10-38-20-20-24 | TT | 10 | 38 | 20 | 1 | 20 | 24 | 24099 | 0 |

| TT-10-38-40-20-24 | TT | 10 | 38 | 40 | 2 | 20 | 24 | 32499 | 0 |

| TT-10-38-60-20-24 | TT | 10 | 38 | 60 | 3 | 20 | 24 | 40900 | 0 |

| TT-10-38-80-20-24 | TT | 10 | 38 | 80 | 4 | 20 | 24 | 49300 | 0 |

| TT-10-38-25-25-24 | TT | 10 | 38 | 25 | 1 | 25 | 24 | 25332 | 0 |

| TT-10-38-50-25-24 | TT | 10 | 38 | 50 | 2 | 25 | 24 | 34965 | 0 |

| TT-10-38-75-25-24 | TT | 10 | 38 | 75 | 3 | 25 | 24 | 44599 | 0 |

| TT-10-38-100-25-24 | TT | 10 | 38 | 100 | 4 | 25 | 24 | 54232 | 0 |

| TT-10-38-30-30-24 | TT | 10 | 38 | 30 | 1 | 30 | 24 | 26749 | 0 |

| TT-10-38-60-30-24 | TT | 10 | 38 | 60 | 2 | 30 | 24 | 37799 | 0 |

| TT-10-38-90-30-24 | TT | 10 | 38 | 90 | 3 | 30 | 24 | 48850 | 0 |

| TT-10-38-120-30-24 | TT | 10 | 38 | 120 | 4 | 30 | 24 | 59900 | 0 |

| TT-10-46-20-20-20 | TT | 10 | 46 | 20 | 1 | 20 | 20 | 27210 | 0 |

| TT-10-46-40-20-20 | TT | 10 | 46 | 40 | 2 | 20 | 20 | 35611 | 0 |

| TT-10-46-60-20-20 | TT | 10 | 46 | 60 | 3 | 20 | 20 | 44011 | 0 |

| TT-10-46-80-20-20 | TT | 10 | 46 | 80 | 4 | 20 | 20 | 52411 | 0 |

| TT-10-46-25-25-20 | TT | 10 | 46 | 25 | 1 | 25 | 20 | 28443 | 0 |

| TT-10-46-50-25-20 | TT | 10 | 46 | 50 | 2 | 25 | 20 | 38077 | 0 |

| TT-10-46-75-25-20 | TT | 10 | 46 | 75 | 3 | 25 | 20 | 47710 | 0 |

| TT-10-46-100-25-20 | TT | 10 | 46 | 100 | 4 | 25 | 20 | 57343 | 0 |

| TT-10-46-30-30-20 | TT | 10 | 46 | 30 | 1 | 30 | 20 | 29860 | 0 |

| TT-10-46-60-30-20 | TT | 10 | 46 | 60 | 2 | 30 | 20 | 40911 | 0 |

| TT-10-46-90-30-20 | TT | 10 | 46 | 90 | 3 | 30 | 20 | 51961 | 0 |

| TT-10-46-120-30-20 | TT | 10 | 46 | 120 | 4 | 30 | 20 | 63011 | 0 |

| TT-10-46-20-20-24 | TT | 10 | 46 | 20 | 1 | 20 | 24 | 28139 | 0 |

| TT-10-46-40-20-24 | TT | 10 | 46 | 40 | 2 | 20 | 24 | 37004 | 0 |

| TT-10-46-60-20-24 | TT | 10 | 46 | 60 | 3 | 20 | 24 | 45869 | 0 |

| TT-10-46-80-20-24 | TT | 10 | 46 | 80 | 4 | 20 | 24 | 54734 | 0 |

| TT-10-46-25-25-24 | TT | 10 | 46 | 25 | 1 | 25 | 24 | 29372 | 0 |

| TT-10-46-50-25-24 | TT | 10 | 46 | 50 | 2 | 25 | 24 | 39470 | 0 |

| TT-10-46-75-25-24 | TT | 10 | 46 | 75 | 3 | 25 | 24 | 49568 | 0 |

| TT-10-46-100-25-24 | TT | 10 | 46 | 100 | 4 | 25 | 24 | 59666 | 0 |

| TT-10-46-30-30-24 | TT | 10 | 46 | 30 | 1 | 30 | 24 | 30789 | 0 |

| TT-10-46-60-30-24 | TT | 10 | 46 | 60 | 2 | 30 | 24 | 42304 | 0 |

| TT-10-46-90-30-24 | TT | 10 | 46 | 90 | 3 | 30 | 24 | 53819 | 0 |

| TT-10-46-120-30-24 | TT | 10 | 46 | 120 | 4 | 30 | 24 | 65334 | 0 |

| TT-10-58-20-20-20 | TT | 10 | 58 | 20 | 1 | 20 | 20 | 35440 | 0 |

| TT-10-58-40-20-20 | TT | 10 | 58 | 40 | 2 | 20 | 20 | 46124 | 0 |

| TT-10-58-60-20-20 | TT | 10 | 58 | 60 | 3 | 20 | 20 | 56807 | 0 |

| TT-10-58-80-20-20 | TT | 10 | 58 | 80 | 4 | 20 | 20 | 67490 | 0 |

| TT-10-58-25-25-20 | TT | 10 | 58 | 25 | 1 | 25 | 20 | 36673 | 0 |

| TT-10-58-50-25-20 | TT | 10 | 58 | 50 | 2 | 25 | 20 | 48590 | 0 |

| TT-10-58-75-25-20 | TT | 10 | 58 | 75 | 3 | 25 | 20 | 60506 | 0 |

| TT-10-58-100-25-20 | TT | 10 | 58 | 100 | 4 | 25 | 20 | 72422 | 0 |

| TT-10-58-30-30-20 | TT | 10 | 58 | 30 | 1 | 30 | 20 | 38090 | 0 |

| TT-10-58-60-30-20 | TT | 10 | 58 | 60 | 2 | 30 | 20 | 51424 | 0 |

| TT-10-58-90-30-20 | TT | 10 | 58 | 90 | 3 | 30 | 20 | 64757 | 0 |

| TT-10-58-120-30-20 | TT | 10 | 58 | 120 | 4 | 30 | 20 | 78090 | 0 |

| TT-10-58-20-20-24 | TT | 10 | 58 | 20 | 1 | 20 | 24 | 36533 | 0 |

| TT-10-58-40-20-24 | TT | 10 | 58 | 40 | 2 | 20 | 24 | 47762 | 0 |

| TT-10-58-60-20-24 | TT | 10 | 58 | 60 | 3 | 20 | 24 | 58992 | 0 |

| TT-10-58-80-20-24 | TT | 10 | 58 | 80 | 4 | 20 | 24 | 70222 | 0 |

| TT-10-58-25-25-24 | TT | 10 | 58 | 25 | 1 | 25 | 24 | 37766 | 0 |

| TT-10-58-50-25-24 | TT | 10 | 58 | 50 | 2 | 25 | 24 | 50228 | 0 |

| TT-10-58-75-25-24 | TT | 10 | 58 | 75 | 3 | 25 | 24 | 62691 | 0 |

| TT-10-58-100-25-24 | TT | 10 | 58 | 100 | 4 | 25 | 24 | 75154 | 0 |

| TT-10-58-30-30-24 | TT | 10 | 58 | 30 | 1 | 30 | 24 | 39183 | 0 |

| TT-10-58-60-30-24 | TT | 10 | 58 | 60 | 2 | 30 | 24 | 53062 | 0 |

| TT-10-58-90-30-24 | TT | 10 | 58 | 90 | 3 | 30 | 24 | 66942 | 0 |

| TT-10-58-120-30-24 | TT | 10 | 58 | 120 | 4 | 30 | 24 | 80822 | 0 |