WORK AREA CRANES

CraneVeyor offers Work Area Cranes ranging from 250 to 4,000 lbs capacity for various industrial applications. Models include the TranStation Series (pre-engineered enclosed track systems designed for maximum efficiency and ergonomic performance).

These cranes are designed for efficiency, durability, and compatibility with different workspace configurations.

Work Area Crane Models

Four models designed for every lifting requirement

- Max SpanUp to 20'

- Max Height12'

- Push Ratio1:100

- Floor Req.5" concrete

- Best ForLight Assembly

- Max SpanUp to 28'

- Max Height15'

- Push Ratio1:100

- Floor Req.5" concrete

- Best ForManufacturing

- Max SpanUp to 32'

- Max Height16'

- Push Ratio1:100

- Floor Req.5" concrete

- Best ForHeavy Manufacturing

- Max SpanUp to 34'

- Max Height18'

- Push Ratio1:100

- Floor Req.5" concrete

- Best ForIndustrial Operations

Interested? Contact us

See the following TranStation Free Standing Crane information:

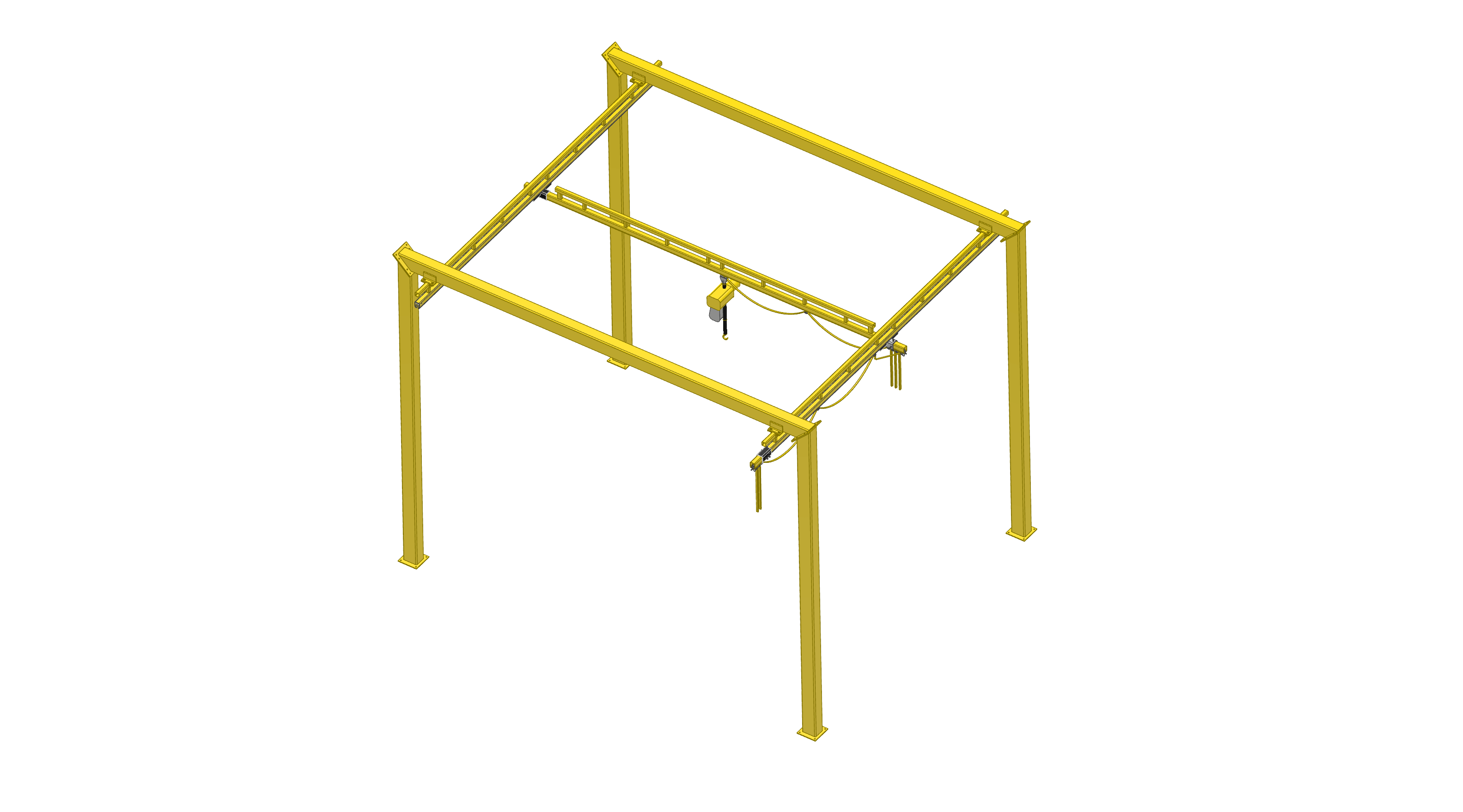

Free Standing TranStations are entirely self-supporting and independent of the building structure, with no need for bracing or building tiebacks, and only require a 5" concrete slab. Other "free standing" systems need help to stand alone and require sway bracing to reduce movement and at least a 6" reinforced concrete floor for support. Since no extra support is required Free Standing TranStations are the best choice for outside installations and other open areas.

The Free Standing structure is engineered to rugged seismic requirements. You receive the benefits of a more rigid and durable system as a standard. The rigid frame has unique 45degree connections and structurally rigid runway connections. Structural steel tubing is used for the frames and all bolted ASCE approved connections are provided, unlike other manufacturers who use clamp/slip connections. The low profile design requires minimum headroom. The modular design makes it easy to add sections or to relocate.

Because TranStation cranes are so easy to move the runways must be level. Columns are installed using anchors with leveling nuts for up to 1" adjustment of the columns to compensate for uneven floors. For more deviation, columns can be ordered different heights. The bases are grouted after leveling for full bearing on the slab (nominal 5", 2500 psi concrete) so soil bearing pressure under the slab is less than the 1000 psf.

Systems are pre-engineered, easy to order, simple to layout and easy to install. There are hundreds of models for 250# thru 4000# capacity, 34' bridge lengths, up to 18' hook bearing height, 30' runway spans, and unlimited runway lengths. Select the model closest to your requirement and we will adjust the details to your requirements. A dimension drawing is provided for your review and approval prior to manufacture.

TranStation Free Standing systems include:

- Enclosed track bridge, with end trucks, stops and trolley for a hook-on hoist/device.

- Enclosed track runways, complete with support frames, hanger assemblies, splice assemblies and mounting hardware. Even the floor mounting bolts and grout are included.

- Festooned electrical system for bridge and runway, complete with trolleys, 4-conductor #14 flat cable, clamps and stack-up system.

- A layout drawing, assembly instructions, and manuals are provided with each system.

Universal Features Across All TranStation Models

Engineering excellence in every component

Structural Design

Self-Supporting: Entirely independent of building structure with no bracing required.

Seismic Rated: Engineered to rugged seismic requirements with unique 45 degree connections.

Advanced Wheel Assembly

Precision Engineering: Machined steel wheels with sealed, lifetime lubricated ball bearings.

Tapered Design: Wheels tapered to match track, reducing rolling resistance.

Enclosed Track System

High Strength: Low weight, high-strength steel construction.

Self-Cleaning: Tapered rolling surface stays clean and reduces wheel wear.

Ergonomic Performance

Push Ratio: Only 1 pound of effort moves 100 pounds of load.

Increased Productivity: Effortless movement boosts efficiency.

Complete Electrical Package

Festooned System: 4-conductor flat cable with trolleys on C track.

Bridge and Runway: Complete electrical for motorized operation.

Safety Features

End Stops: Included on all bridges and runways.

Level Adjustable: Up to 1 inch adjustment for uneven floors.

Pre-Engineered System

Easy to Order: Hundreds of models for quick selection.

Simple Layout: Dimension drawings provided for approval.

Floor Requirements

Minimal Slab: Only 5 inch concrete, 2500 psi required.

Outdoor Ready: Best choice for outside installations.

Documentation

Layout Drawing: Detailed drawings for review and approval.

Manuals: Complete operation and maintenance documentation.

Complete Package

Bridge: Enclosed track with end trucks, stops and trolley.

Runways: Support frames, hangers, splices and hardware.

Rigid Construction

45 Degree Connections: Unique structurally rigid connections.

Bolted Joints: All ASCE approved bolted connections.

Quality Assured

20+ Years: Proven design with decades of experience.

Reliable: Trusted by industries worldwide.

Downloads

Technical specifications and brochures